Q: How many components are missing from the driving motor of an electric vehicle compared to an internal combustion engine? 100? 300? Or 500?

The answer is: 1000+

According to incomplete statistics, a conventional internal combustion engine typically has over 1400 components; A drive motor, on the other hand, often only has 100-200 components, reducing nearly 1000 parts.

For some traditional machining tools, equipment, and production lines, these reduced parts are like manual positions replaced by AI.

Data shows that the market demand for specialized machining tools for traditional five major components such as cylinder blocks, cylinder heads, crankshafts, connecting rods, and camshafts is decreasing year by year.

But at the same time, the metal processing project of motors also brings new opportunities. Metal processing projects such as motor shafts, motor shells, and battery brackets have become new growth points.

Although different from mechanical transmission, the precision requirements for processing new energy vehicle components have never decreased. Coupled with the demand for lightweight and the unique and complex shape of parts, they pose even sharper challenges to tool and machine tool suppliers.

Precision machining of large diameter main hole in motor casing

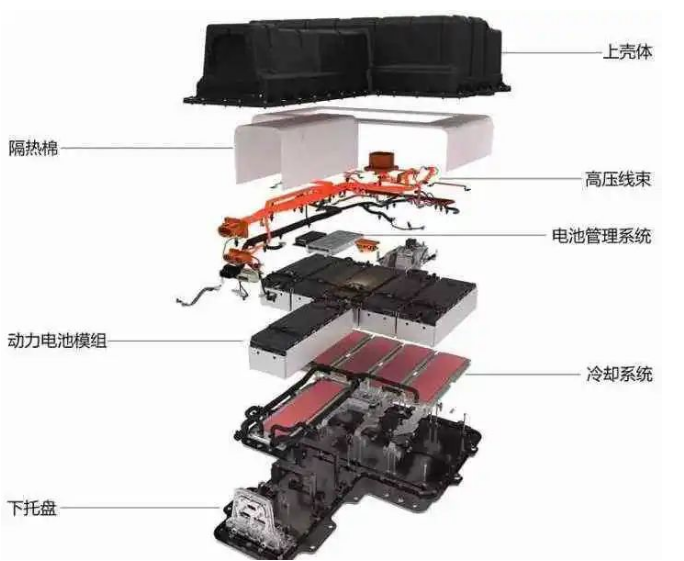

The aperture size of the main hole in the motor casing depends on the size of the stator. Due to the high energy density required by electric vehicles, the coil diameter on the rotor needs to be within a reasonable range.

The stator diameter of the motor used in general electric vehicles should be at least φ Above 200mm, which means that the diameter of the main hole in the motor casing must also be within φ Above 200mm.

For tool making, φ 200mm is already a large diameter tool.

In order to minimize energy loss, the coordination between components such as the motor casing/motor shaft/stator must be optimized to the most reasonable range.

Therefore, in the field of machining, there are particularly strict requirements for the machining content of motor shells, especially the shape and positional tolerances of the main hole and bearing hole. In addition, in order to improve power density, the motor should be as light and small as possible, which also requires perfect control of the wall thickness of the motor shell.

Overall, high accuracy, large diameter, and easy deformation of thin walls are the main characteristics of current motor shell machining.

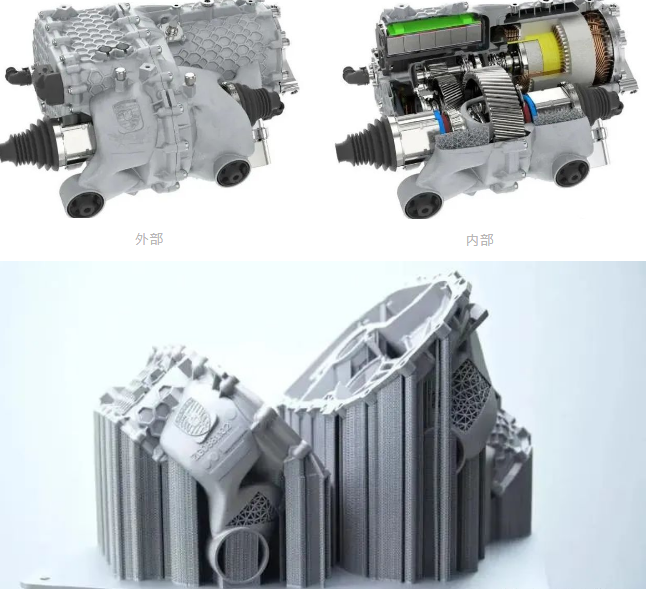

To ensure machining accuracy, the current cutting tools adopt the concept of guide bar cutting tools, which can achieve µ level adjustment in size.

The supporting guide strip plays a role in supporting, guiding, and absorbing vibration, and the design of the guide strip can offset deformation during deep hole processing.

More importantly, the weight of the tool is one of the factors that constrain the design scheme of the guide bar type tool. If traditional tool design concepts are adopted, a tool with such a large diameter should weigh at least 25Kg.

In order to adapt to the concept of modern machine tool high-speed machining, reducing the weight of such tools is a particularly critical technical challenge.

With the development of 3D printing technology and metal materials, Kenna in the United States took the lead in adopting advanced 3D printing and composite material application technology, solving the problem of tool weight reduction, and can manufacture guide bar type tools up to 15Kg at the lightest.

Furthermore, it is worth noting that Porsche has previously launched its first motor housing that is entirely manufactured using 3D printing and additional manufacturing technology.

The shell adopts high-quality aluminum alloy powder layer by layer 3D printing, combined with laser metal fusion technology.

The final metal 3D printed shell is 10% lighter than traditional castings, and although the thickness is only 1.5mm, its stiffness is even stronger than similar parts without honeycomb structure.

Muchas gracias. ?Como puedo iniciar sesion?