Based on the long-term cooperative relationship between both parties, ABB collaborates with Microsoft to integrate Azure OpenAI services into ABB Capability ™ Genix Industrial Analysis and AI Suite. Both parties will be committed to implementing generative AI technology to help industrial customers unlock hidden insights in operational data. The improvement of data collection and governance capabilities will significantly improve efficiency and productivity, enhance asset reliability and operational safety, reduce energy consumption, and reduce environmental impact.

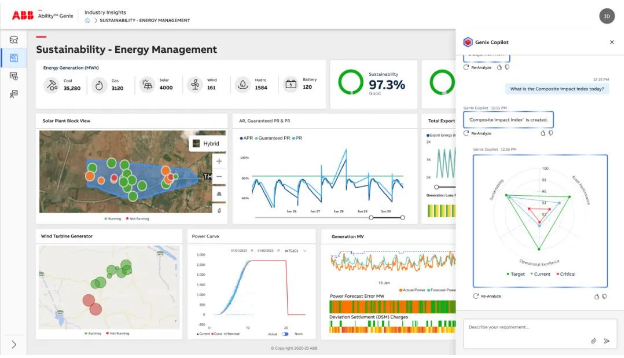

ABB will integrate generative AI into Genix platform and applications through Azure OpenAI services, including large language models (LLMs) such as GPT-4, to achieve many functions such as code, image and text generation. After release, the new Genix Copilot application will provide intuitive functionality and simplify the associated data flow of various processes and operations to enhance the user experience. By providing real-time executable insights to industry managers, functional experts, and workshop engineers, we improve the quality of decision-making and increase productivity. Such insights are expected to extend the asset lifecycle by up to 20% and reduce unexpected downtime by up to 60%.

In addition, this solution can provide advanced monitoring and optimization insights for industrial greenhouse gas emissions and energy utilization, helping customers achieve sustainable development and energy transformation goals.

Genix Copilot can also gain experience from operational personnel, promote joint decision-making among various positions, and pay special attention to protecting data and cognitive security within the enterprise.

ABB Ability ™ Genix is a comprehensive modular Internet of Things, analysis and AI platform for the chemical industry. It has implanted specific industry domain knowledge to drive business performance while protecting customers’ original investment. Enterprises running Genix have witnessed up to 40% cost savings in operations and maintenance, up to 30% improvement in production efficiency, and 25% improvement in energy efficiency and emission optimization. With the addition of generative AI functionality, Genix is expected to further expand these advantages.

Rajesh Ramachandran, Global Chief Digital Officer of ABB Process Automation Business Unit, stated that,

This is an important step in the strategic cooperation between ABB and Microsoft, which is conducive to accelerating the Digital transformation of the industrial sector. We believe that Genix Copilot will help industrial clients achieve comprehensive goals of sustainable development, excellent operations, and improved asset performance. Expanding generative AI capabilities in ABB’s industrial digital solutions will lead customers towards a new era of AI empowering massive decision-making.

Ralph Hautter, President of Microsoft Europe, Middle East, and Africa, stated that,

We believe that the modernization and scaling of data platforms are important guarantees for the long-term success of enterprises. The use of advanced digital capabilities such as Azure OpenAI services will help enhance ABB Genix to effectively manage related data, while promoting Digital transformation, and inject source power for improvement and continuous change.

Genix integrates data from enterprise operations (OT), information (IT), and engineering (ET) through automation, unleashing the power of data and applying industrial AI to further enhance analysis and optimization capabilities. This platform can seamlessly scale from assets, factories, to enterprises, and be deployed across cloud, hybrid, edge, or local platforms. Its design is secure and reliable, and uses Microsoft Azure to achieve integrated cloud connectivity and services.

Important notes on forward-looking information

This press release contains forward-looking information and statements. Such information can generally be identified by including “expect”, “think”, “estimate”, “target”, “plan”, “may”, “intend” or similar words. However, various risks and uncertainties still exist, many of which are beyond our control. These risks and uncertainties may result in substantial differences between the actual results and the forward-looking information and statements made in this press release, and may affect our ability to achieve some or all of the stated goals. Although ABB believes that the expectations reflected in such forward-looking statements are based on reasonable assumptions, there is no guarantee that these expectations will be realized.