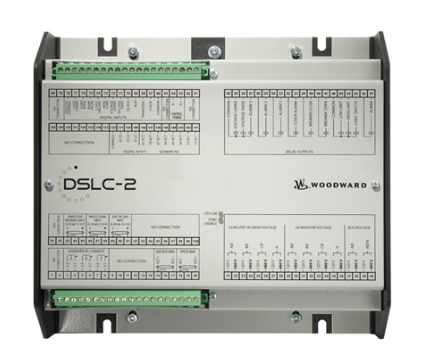

Woodward DSLC-2 ™ (Digital Synchronizer and Load Control) is a microprocessor based synchronizer and load control designed for three-phase AC generators. DSLC-2 integrates synchronizers, load sensors, load control, dead bus closure system, VAR, power factor, and process control into a powerful software package.

Features and functions

Woodward DSLC-2 ™ (Digital Synchronizer and Load Control) is a microprocessor based synchronizer and load control designed for three-phase AC generators. DSLC-2 integrates synchronizers, load sensors, load control, dead bus closure system, VAR, power factor, and process control into a powerful package.

The application allows for precise parallel connection and control of up to 32 generators. The dedicated Ethernet system provides seamless communication between DSLC-2 and MSLC-2 units. Provide a second Ethernet port for remote customer control and monitoring using Modbus TCP, enabling easy DCS and PLC connection. Modbus RTU can be used through a separate RS-485 port.

Redundant Ethernet networks can be achieved through two Ethernet ports.

Woodward developed a new DSLC-2 using the existing solid state DSLC and combining it with an additional decade of application experience. DSLC-2 performs well in both simple and complex generator system applications. The DSLC-2/MSLC-2 combination provides multi unit, segmented, utility, and tie breaker control for complex power systems.

Features include:

A dedicated Ethernet network for precise system communication between all DSLC-2 and MSLC-2 reduces system wiring.

Ethernet Modbus TCP and Modbus RTU for remote control and monitoring.

Redundant Ethernet communication improves reliability.

The ‘System Update’ function allows the deletion or addition of generator sets.

The new DSLC-2 can be configured for multiple applications.

The integrated DSLC-2 and MSLC-2 system functions do not require redundant sensors (such as PT, CT, and MOP) connected to separate modules such as load sensors and synchronizers.

The installation and size reduction of the rear panel can release door space and facilitate wiring.

No additional relay logic is required to control the dead bus shutdown.

The slip frequency parallel connection, voltage matching, and speed deviation transmission between the synchronizer and load control can achieve smooth parallel connection without the risk of reverse power tripping.

Three phase true RMS power sensing enables DSLC-2 control to maintain accuracy even in the event of phase load imbalance and voltage fluctuations.

When a transformer is included in the system, the phase angle correction of GCB is achieved.

Woodward ToolKit ™ The software allows for flexible settings using the same basic menu tree and overview screen as the original DSLC. The graphical overview and trends of generator and busbar parameters make DSLC-2 debugging more user-friendly. All Woodward devices can be programmed through a single connection to the network.

The toolkit can be accessed through one of the Ethernet ports or RS-232 port.