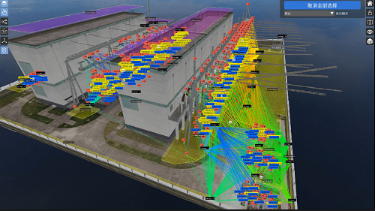

Intelligent substation 3D modeling, converter station maintenance based on 3D models, 3D intelligent inspection

By utilizing technologies such as 3D laser point cloud acquisition, digital elevation modeling, and high-precision surveying, each line, tower, and component is assigned exclusive 3D coordinates, with positioning accuracy reaching centimeter or even millimeter levels. This is the bridge between the real world and the digital virtual world built by the power industry through digital twins.

In the process of constantly being seen by the industry as a digital twin, the ideal digital twin of Uni Tech is to achieve remote collaborative work between people and remote control of both on-site and off-site operations on a three-dimensional scene based on precise GIS information. The implementation of these operations only requires a mobile phone or a PC

Intelligent inspection, algorithm first

A complete manual inspection of a 50MW substation covering all equipment usually takes 2-3 months, while machine inspection only takes about 2 days.

Under the urgent need of replacing manual routine inspections, light out inspections, and some special inspections with the new generation of centralized monitoring systems and remote intelligent inspection systems in substations, accelerating the construction and application of intelligent inspection in substations, expanding the coverage of intelligent inspection in substations, has already become one of the scenarios where the digital twin technology of Uni Tech sinks into practical applications.

Youli 3D Intelligent Inspection System

At present, based on the mining of power industry data from massive amounts of data, Unitech has applied more than ten cases in the power industry, gradually deepening its application.

In the past, people would have thought that digital twins could simply build a visualization system for a substation by establishing a dynamic digital substation model and connecting it to the model based on the actual installation location of the camera signal

Zhang Xuebing, founder and CEO of Unitech, explained that in the past, the industry has indeed made many “good-looking” attempts in digital twin projects, mainly relying on manual modeling. In addition to the high investment in data modeling, the “one image” produced can only run on workstations and appear on large screens, unable to be accessed by mobile phones or browsers, and is getting further and further away from users.

As more and more customers, especially those on the enterprise and government sides, are unwilling to spend a lot of money on the “flower racks” prepared for inspection, enterprises represented by Uni Technology that truly do real-time 3D applications have become eye-catching in practical applications.

What changes have taken place in the actual application of digital twin technology compared to the original so-called “intelligent inspection”?

Zhang Xuebing introduced that, In the space of digital twins, we first make a basic calculation, which is to calculate whether the cameras currently deployed by units such as the power grid have met the inspection needs of enterprises for all equipment inspection points according to the corresponding specifications and standard list of equipment inspection points in the power grid field. After all, some equipment installation positions are very high, some are six meters high, and even some are as high as ten meters, forming a large three-dimensional space

However, the coverage rate of cameras in the power sector in various provinces is generally difficult to exceed 70%: in the past, the deployment of cameras was achieved by camera manufacturers based on experience and on-site surveys.

Uli Technology’s intelligent inspection camera point optimization service provides relatively cost-effective coverage solutions for customers in the power industry through intelligent algorithms in three-dimensional space. Is the installed location the user needs to be inspected, and what areas have not been covered yet? How can I add them? If they have not been installed yet, where should they be installed

Optimization service for placement of Youli intelligent cameras

Innovative Application of Point Cloud Algorithm in Power Grid

Undoubtedly, the demand for digital and intelligent transformation of the power grid has been constantly changing since the initial entry of digital twins into the field of electric power.

In the past, the “digital twin of visualization mode” was essentially a combination of various types of data, and such combinations appeared to be together on the surface. Once proprietary analysis was used, it would be found that these data from different sources and levels were not interconnected, making it difficult to flexibly integrate and apply them.

The above is also the reason why many customers believe that the value of digital twins is not high.

Nowadays, the digital twin has truly entered the stage of creating value from good-looking, and behind the release of power data value by Unitech, it is its gradually deepening understanding of the power grid field.

Zhang Xuebing pointed out that the power grid field has high requirements for accuracy, especially for substation facilities and substations, which require closure accuracy of over 99.99%. He hopes to use millimeter level accuracy data to accurately analyze and judge the status of power inspection.

In practical applications, using visible light cameras during the day can easily monitor and track targets. However, at night, visible light cameras have certain limitations and are greatly affected by weather, resulting in significant interference with visible light imaging in environments such as rain, clouds, and nighttime.

Because of this, unlike most companies on the market that use manual modeling models to build 3D applications, Unitech has created a set of 3D intelligent inspection systems based on high-precision laser point clouds in substations, which are controlled by high-precision 3D color point clouds and cameras.

Compared with ordinary laser point cloud data, Uni Tech’s ultra high precision laser point cloud data comprehensively surpasses in terms of restoration, aesthetics, and practicality. Based on ultra-high precision laser point cloud data, the entire station model can achieve millimeter level accuracy, with a point density of 200000 points/square meter, an average error of within 2MM, and a maximum error of no more than 6MM.

The system utilizes high-precision point clouds for point labeling, and mobilizes detection equipment such as cameras, inspection robots, drones, and auxiliary control equipment to obtain video and photo data. Hidden table and defect information are analyzed through background image recognition and displayed on a 3D model.

Based on the achievements of LiDAR point cloud technology and the integration of visible light shadow image data, Uni Tech customizes inspection tasks remotely, controls station video monitoring and robots to carry out inspections. Based on real-time perception of the inspection situation in real life 3D, intelligent analysis is performed on the obtained visual images, and abnormal equipment is automatically tracked. Combined with real-time equipment signals, alarm monitoring and fault linkage are achieved, achieving remote intelligent three-dimensional inspection.

In the words of Zhang Xuebing, Youli Technology can be considered as the first enterprise in China to apply new terminal equipment such as LiDAR in large substations and DC stations, and provide corresponding operation and maintenance services.

A diagram of a three-dimensional power grid, based on a three-dimensional engine platform

Throughout the entire power industry market, there are not few companies that have entered the bureau. Including large companies such as Alibaba and Huawei, they are also using their own advantages such as cloud platforms to occupy a certain market share

For Uni Technology, assisting on-site operation, maintenance, and decision-making of power units is a decision that enterprises are facing in the current era of digital and intelligent demand.

Zhang Xuebing stated that power facilities are scattered throughout the country, including those at the provincial, city, county, and town levels, with a large amount of relevant data. In terms of this data volume, it requires both comprehensive coverage of high-precision data and massive computing power and storage. The processing power of the data management engine and the requirements for the system base platform are not low.

And the 3D data management engine of Unitech is the key to its entry into the practical digital twin world.

It is reported that Unitech’s domestically developed 3D data management engine can load massive 3D data in seconds, first solving the problem of “viewing” real-world GIS data; In addition to GIS, the engine also supports various structural formats of 3D models, which can be loaded quickly and losslessly on one platform; Support data storage in the cloud or locally, and collaborative work by multiple people.

Using the self-developed patented UDS format, Uni Tech’s infinite detail 3D engine can efficiently compress point clouds and high-precision 3D models. The UDS format has a compression rate of over 60% for LAZ format laser point clouds, with a conversion efficiency of 1GB/minute, which can greatly save storage resources and space. Based on the octree structure, local rendering characteristics of 3D data are achieved through CPU computing power.

Relatively speaking, the data confidentiality and security requirements in the power grid field are high, and everything needs to operate within a secure environment within the network system. To some extent, the rapid download capability of large-scale data mentioned above has sunk into the field of power grids, providing unlimited possibilities for the safe operation and maintenance of data assets for one map in the province and even for the future nationwide.

When it comes to the business layout of Unitech, Zhang Xuebing candidly stated that the company packages its products through specific projects, while the products that sink into applications always revolve around the construction of independent platforms. The company’s existing product solutions largely rely on the company’s underlying 3D data base platform. This platform is currently recognized as a security platform system in the digital transformation process of power systems such as State Grid or Southern Power Grid

Looking ahead to the future, we need to shift from unmanned patrols to unmanned inspections, and expand from some pilot cities to nationwide deployment. We still need to leverage the long-term efforts of Uni Tech to maintain cooperation with the outside world. It can be confirmed that achieving the integration of viewing, computing, and storage is crucial if one wants to continue to improve in applications.

Eulee Technology is a core technology provider for digital twins and metaverse, focusing on providing high-tech enterprises with 3D data management, digital twin creation, and applications. We are committed to using 3D technology to build a twin world where everything is connected and empower multiple industries.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.