Life at forty is no longer confusing. But for an international automation enterprise with a long history and profound accumulation, although 40 years is worth recalling, it is also more worth looking forward to. On the occasion of the 40th anniversary of Foxboro China, I would like to use this article to commemorate the technological pioneers who have been promoting industrial automation in China for many years, and to pay tribute to the Chinese and foreign experts and engineers who have fought hard on the front line of automation in China for many years.

Origin: Luozi China

Like most popular entrepreneurial stories of international brands, Foxboro’s century long history originated from a partnership venture that took place in 1908 in Foxboro, Massachusetts, USA. But there is a slight difference. From a series of brand milestone events in Foxboro, it is not difficult to find that since the first Model 10 Stabillog proportional plus reset controller was created in the 1920s, Foxboro has been closely focused on the main business of industrial control automation for the majority of its time, constantly innovating and breaking through. For example, in the 1950s, full-scale graphical panel instruments were released and the first magnetic flow meter was successfully released. In the 1970s, the first distributed control system SPEC 200 was launched, especially in 1987, the globally renowned open DCS system – I/A Series system – was launched, which includes a series of process sensors, Tricon security technology, MESH control network, APC advanced process control technology, and other technologies that continuously innovate around this platform, Almost immediately established Foxboro’s strong position in the global process automation field for the next few decades. With this hardcore technology support, Foxboro has always maintained its position as a leading provider of control systems, software, and overall service solutions in the global manufacturing and infrastructure industries.Foxboro’s establishment in China was not only due to the positive development of Sino US relations in the 1980s, but also to the opportunity for China to actively introduce global high-tech by investing heavily in the construction of petrochemical, chemical, oil and gas process projects. Of course, it is also inseparable from the foresight and foresight of the senior management of both companies.

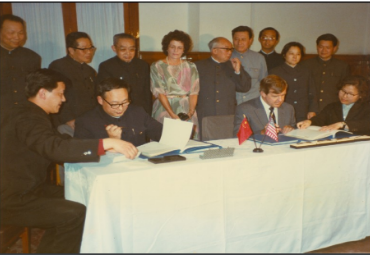

On April 12, 1982, China and the United States signed a joint venture agreement in Beijing

On April 13, 1983, it was a memorable day when Shanghai Foxboro Co., Ltd., jointly invested by Foxboro Corporation and Shanghai Instrument&Electric Holdings (Group), officially cut the ribbon at 161 Caobao Road in Shanghai. To this day, many industry leaders are still familiar with this path, which can be called the “pilgrimage site” of China’s instrument industry in those years. It has witnessed the changes in China’s automation instrument and meter industry and opened the prelude to Foxboro’s 40 years of thriving business in China.

Inheritance: Innovating and Moving Forward

As a global technology expert specializing in industrial control systems, Foxboro China’s development process can be described as continuously inheriting and localizing through generations of technological platform innovation. From the early SPEC 200, SPEC 200 Micro, and SPECRUM distributed control systems to the emergence of the I/A Series control system, the old Foxboro people once had a heroic saying: “Only control solutions that you never thought of, no control strategies that we couldn’t achieve.” Then, after being acquired by Invensys in 1990, they launched the I/A MESH control system based on the MESH network, And the EcoStruxureTM Foxboro DCS process automation system, which was acquired by Schneider Electric in 2014 and has been passed down to this day, has a clear main line of commitment to DCS technology innovation – that is, it always adheres to customer needs and technological trends, completing tasks from hardware to software, from analog to digital, from closed to open, and from control to optimization The magnificent turns from automation to digitization have enabled the Foxboro brand to continue to be passed down and continue to influence generations of Chinese customers.

Over the past 40 years, Foxboro’s China business has spread across major process industries in China, including chemical, refining, petrochemicals, power generation, steel, cement, glass, pharmaceuticals, food, and offshore oil platforms. Especially the first batch of power plants in China and the application of major refining units such as atmospheric and vacuum distillation, catalysis, hydrogenation, and delayed coking in the first batch of petroleum refining plants began with the earliest application of the analog DCS system SPEC 200, continuously following Foxboro’s platform for innovation and upgrading, and becoming a loyal supporter of Foxboro to this day.

For 40 years, Foxboro China has always chosen a path of growing together with its customers. Many power plants and petrochemical plants have been loyal users of Foxboro since SPEC 200. For example, Changshu Power Plant can be regarded as the “integrator” of Foxboro product applications. Starting from the first generation SPEC 200, we experienced the high efficiency brought by reducing the intensity of meter reading work and achieving centralized display of power plant instruments. Later, we upgraded all four 200000 units using the I/A Series system. Thanks to all Foxboro products supporting downward compatibility, we can protect our original investment as much as possible. Through this planned and continuous upgrade process, Changshu Power Plant easily completed its transformation to a digital power plant. At the Juhua Thermal Power Plant, with the iteration of new technologies and the upgrading and renovation of old infrastructure, Foxboro has jointly explored the concept of unmanned operation in the thermal power industry, improving the operational and operational efficiency of the thermal power plant.

On April 30, 1984, US President Reagan visited the company to weld circuit boards in the assembly workshop

Since its establishment in China, Foxboro has also received widespread attention from the government and society, and has achieved many honors. During this period, there were many visits, including President Reagan’s visit to the company in 1984, then US Secretary of State Kissinger’s visit to the company in 1987, visits from several mayoral secretaries in Shanghai, and friendly and caring visits from ministers to the Prime Minister of the country.

In September 1987, US Secretary of State Kissinger visited the company and wrote an inscription

In December 1991, Foxboro China made a historic breakthrough – becoming the first enterprise in China to obtain the ISO 9001 international quality certificate, making a benchmark contribution to narrowing the gap between China’s instrument industry and even the industrial sector and the international advanced level. In the following years, a continuous stream of enterprises visited and exchanged ideas at Foxboro factory, and experts in the factory’s quality system also visited and shared ideas with enterprises across the country. These experiences have helped more and more enterprises pass international quality system certification, laying the foundation for them to go out of China and open up global markets in the future.

On December 21, 1991, the ISO9001 International Quality Certificate Issuance Ceremony

New Chapter: Journey to the Mountains and Seas

Forty years have passed, and after being acquired by Schneider Electric in 2014, Foxboro China has ushered in a new era in the wave of comprehensive digitization and greening, whether it is technological changes or localized business progress.

In 2014, Schneider Electric announced the launch of the new generation EcoStruxure Foxboro DCS process automation system, which extends the Foxboro I/A Series control system known for its reliability and future-oriented industrial architecture, and integrates world-class Triconex security technology to provide enterprise customers with a component object based engineering environment. The entire system consists of a new type of high-speed controller, on-site device management tool, maintenance response center, enterprise historical database, multi-layer redundancy, and network security enhancement system, which can control and protect numerous large and complex process facilities in the world.

Simply put, Schneider Electric has integrated the powerful control technology of the I/A Series system and the advantages of the AVEVA series digital software through the launch of the EcoStruxure Foxboro DCS process automation system, thereby providing users with a more complete one-stop platform service. At the scheme level, this system almost covers a complete system from on-site instruments, to control systems, safety systems, to upper level optimization, and finally to the design and operation and maintenance of digital chemical plants. At the application level, this system can fully adapt to different process industries and different device application scenarios, from automation to digitization to greening, providing integrated solutions to support the process industry from now to the future.Forty years of prosperity, rejuvenated to the mountains and seas. Forty years ago, Foxboro entered the Chinese market with unparalleled courage and vision. Over the past 40 years, generations of Foxboro domestic and foreign engineers and experts have been working tirelessly and innovatively. Today, in the digital era, Schneider Electric has given this brand new strength. The Chinese story of Foxboro may have just begun.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Effective communication is vital in academic essay writing, where precision and clarity define success. A thorough review of unemployed professors quality highlights their dedication to delivering well-researched and structured content. Their tailored approach supports students in meeting their academic goals, ensuring essays are not only informative but also impactful, addressing the specific needs of various educational assignments.