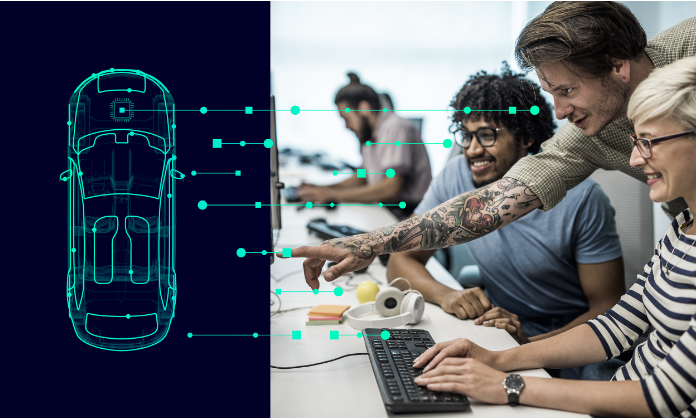

Siemens Digital Industrial Software collaborates with Arm and AWS to provide the PAVE360 digital twin solution in AWS cloud services, utilizing cloud based automotive simulation to accelerate innovation in next-generation software defined vehicles (SDVs)

Developers can now use the Arm technology included in PAVE360 on AWS to quickly develop automotive systems

Siemens Digital Industrial Software further expands its partnership with Amazon Cloud Technology (AWS) by launching a digital twin solution for automobiles based on Siemens PAVE360 in AWS’s cloud services. Through parallel development of software and hardware, the design process of “software defined vehicle” (SDV) is “left shifted” to help developers compress the design cycle and accelerate product launch speed, Assist the automotive industry in accelerating innovation. In addition, Siemens has deepened cooperation with Arm to help developers use Arm running in Siemens PAVE360 digital twin solution through AWS cloud services ® Technology.

Nowadays, car manufacturers do not need to deploy software internally and can directly use the PAVE360 solution provided in AWS cloud services to conduct software development early in their IP selection and design process, and evaluate key systems and software components based on ARM. The solution executed in the cloud can provide developers with simulation speed that traditional local modeling and simulation infrastructure cannot match. It not only helps them fully utilize the advantages brought by process “left shift”, meet the increasingly tight time to market requirements, but also can cope with future technological and commercial challenges.

Siemens Digital Industrial Software EDA Global Sales Mike Ellow, Executive Vice President of Service and Customer Support, stated, “The automotive industry is currently facing disruptive changes in multiple aspects, with ‘Software Defined Vehicles’ (SDVs) It is a development direction with great growth potential, and the fiercely competitive SDV market is also facing many pressures. Car companies must quickly respond to consumer expectations for new features while minimizing software development cycles. This trend and demand have greatly promoted the application of the ‘left shift’ method, enabling collaborative development of parallel software and hardware, and continuously transforming towards a comprehensive digital twin direction. Siemens’ collaboration with Arm and AWS can achieve organizational efficiency that traditional development methods currently struggle to achieve

Siemens’ PAVE360 deployed in AWS incorporates Arm IP, which is designed for automotive specific workloads, functional system software, physical world simulation, and algorithm development tools such as Siemens’ Simcenter ™ Developed by Prescan and a mixed fidelity EDA modeling and simulation engine. PAVE360 can seamlessly integrate these resources, not only enabling automotive simulation on engineers’ desktops, but also presenting it in a more integrated and secure cloud environment, significantly reducing manufacturers’ costs and resource requirements, eliminating the need for expensive IT upgrades for high-speed simulation, thereby helping automotive engineers focus more on meaningful improvement work.

Dipti Vachani, Senior Vice President and General Manager of the Automotive Business Line at Arm, stated: “‘Software defined cars’ is the survival path of the automotive industry, requiring new technologies and methods to achieve faster and more agile development. Siemens’ innovative PAVE360 solution can accelerate the development of automotive systems and meet increasingly stringent consumer expectations. We collaborate with Siemens and AWS to support a wide range of use cases on Arm’s automotive platform, covering the entire supply chain from IP evaluation to fleet management.”

Wendy Bauer, Vice President of AWS Automotive and Manufacturing, said, “The digital twin method is becoming increasingly popular in the automotive industry, and AWS can provide it with computing power and infrastructure. By using Siemens’ PAVE360 to map the correct embedded environment to optimized AWS instances, while using ARM’s automotive enhanced IP, OEMs and suppliers can achieve innovative SDV solutions and methods.

Inventory spot module recommendation:

ABB 1SBP260196R1001

WATLOW ANAFAZE temperature controller CLS216 105996005

WOODWARD 505 8200-1302

WOODWARD 505 8200-1300

KONGSBERG DGU 8800E 8200177

WOODWARD 8200-203- ProTech 203 overspeed protection

KONGSBERG MARITIME RMP200-8-603443-REV-1.0.3 MODULE

R901325866+R900775346+R901273425A

I’m curious to find out what blog platform you happen to be using?

I’m having some minor security issues with my latest site and I would like to find something more safe.

Do you have any recommendations?

Dear friend, what can I do for you? Please let me know and I will try my best to solve it for you.

Hello! Someone in my Myspace group shared this website with us so I came to check it out.

I’m definitely loving the information. I’m book-marking and will be tweeting this to my followers!

Wonderful blog and fantastic design and style.

Dear friend, thank you for your recognition and leave a message.

Its like you read my mind! You seem to know so much about this, like you wrote

the book in it or something. I think that you could do with

some pics to drive the message home a bit, but other than that, this is wonderful blog.

An excellent read. I will definitely be back.

Dear friend, thank you for your recognition. I will continue to work hard.

Have you ever thought about including a little bit more than just

your articles? I mean, what you say is important

and everything. Nevertheless just imagine if you added some great images or

video clips to give your posts more, “pop”! Your content is excellent but with images and video

clips, this website could certainly be one of the greatest in its niche.

Very good blog!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.