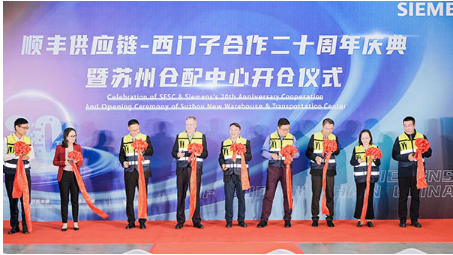

Recently, SF Supply Chain announced that Siemens, a leading technology company in the world, has successfully completed a “seamless relocation” – the Siemens Suzhou new warehouse distribution center has officially opened. This is not only another milestone achievement for SF Supply Chain Services Siemens, but also marks a new journey in the 20-year long cooperation between the two sides in the Chinese market.

Since our collaboration in 2003, SF Supply Chain has relied on decades of accumulated expertise to assist Siemens in building a more resilient supply chain in China, enabling technology to thrive, and creating value for our customers. This year, the original Siemens Suzhou warehouse distribution center needs to be relocated and upgraded due to municipal planning needs. SF Supply Chain once again lived up to expectations, combining past experience, comprehensive planning and deployment, integrating and deepening cooperation advantages, and providing Siemens with more seamless, efficient, and digital supply chain solutions in the East China and national markets:

Senseless warehouse moving with remarkable results

The successful opening of Suzhou New Warehouse Distribution Center has injected the concept of “Senseless Moving”. Through the joint efforts of Siemens and SF Supply Chain, Siemens end users ultimately did not feel the relocation of the Suzhou warehouse distribution center. The project teams of both parties devoted 9 months to business design and scheme preparation, and after 5 months of perfecting the project implementation process deployment, they finally completed the warehouse moving task of over 8000 pallets and nearly 200 vehicles in just 3.5 days ahead of schedule. The excellent performance of zero inventory difference achieved by Siemens has met the high standard requirements for “seamless warehouse moving”.

Scientific design and efficient operation

SF Supply Chain has scientifically designed and optimized the hardware configuration and software management of Siemens Suzhou New Warehouse Distribution Center. The warehouse has a large area, and SF Supply Chain fully considers the higher floor height and lower single storage cost to bring more efficient storage capacity – not only introducing the VNA narrow aisle storage system, but also improving storage efficiency by 20%; We have also increased production capacity by nearly 70% through automated production lines. It is worth mentioning that the optimized storage logic not only increases the number of static picking locations, but also significantly reduces the number of replenishment times.

At the same time, SF Supply Chain has introduced visualization technology and integrated warehouse and distribution services for Siemens Suzhou’s new warehouse and distribution center. With the help of the platform jointly developed by both parties, it is possible to have a clear and real-time understanding of the workload and efficiency of each node on site, and it also provides real-time and reliable support for operations and business decision-making. Not only that, SF Supply Chain has also connected with OTM transportation and logistics management systems, increased barcode scanning of warehouse outgoing boxes, empowered Siemens warehouse and distribution integration management, and successfully improved transportation and receipt accuracy by 50%.

Siemens management stated in their speech: In recent years, the technological industry and market changes have been accelerating. Siemens is committed to innovation, deeply cultivating and developing in China, and constantly sharing innovative technologies and successful practices in the fields of digitalization and low-carbon. Facing the Chinese market with great potential and strong resilience, SF Supply Chain has long helped us deeply enter the logistics system, creating a stable, efficient, and digitally empowered service matrix. The successful relocation and opening of the new warehouse and distribution center in Suzhou is another remarkable achievement “Fruit makes us more flexible and proactive in embracing change, thereby better serving the market and customers.”

At the opening ceremony of Siemens Suzhou New Warehouse and Distribution Center, SF Supply Chain Management summarized and delivered a speech: “We sincerely appreciate Siemens’ long-term support and trust in SF Express’s supply chain. The successful opening of the ‘Senseless Relocation’ of the Suzhou new warehouse distribution center not only serves as a strong witness to our two sides’ brilliant chapter of 20 years, but also as a new starting point for continuous innovation and common progress in future cooperation. Looking forward to the future, we will continue to walk side by side with Siemens, connect the ecosystem, and create new momentum together.”

Warehouse stock recommendation:

A-B PLC communication module 1747-L524

A-B PLC communication module 1747-L543

ABB tension sensor 3BSE004214R1

ABB tension sensor PFTL101BE 2.0KN 3BSE004214R1

ABB tension sensor PFTL101BE 2.0KN

GE ION TRACK ITEMISER3 ENHANCED DESKTOP DETECTOR SYSTEMS

VAF VISCOSENSE-3-0279-0112 INTERFACE BOX

SAM ELECTRONICS-LYNGSO MARINE SIM-401 DUAL SERIAL INTERFACE MODULE

PHOENIX CONTACT UMK-SE 11,25-1 INTERFACE CONVERTERS

PHOENIX CONTACT UMK-SE 11,25 INTERFACE CONVERTERS

niXwvAnHaIKdSKPjcFnKdp

Yes

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.