“I have long wanted to buy new energy vehicles, but I always worry about difficult charging. Although” charging anxiety “brings many troubles, it still cannot stop the development momentum of new energy vehicles.”. With the continuous increase in the number of new energy vehicles in China, charging facilities are facing unprecedented supply-demand contradictions. As one of the “three giants” in the domestic charging industry, Star Charging faces supply chain management challenges brought by business expansion while winning orders and markets.

In this context, Schneider Electric has provided supply chain management consulting solutions to address various supply chain management issues brought about by the rapid expansion of the Star charging business, helping to build a collaborative, robust, agile, and efficient end-to-end supply chain. This has led to a 20% increase in supplier delivery timeliness, a 10% increase in supplier quality qualification rate, a 20% reduction in domestic inventory turnover, and a risk amount of over 24 million yuan. Design a lean production line for key products of DC charging stations, increasing their DC production capacity by 25%.

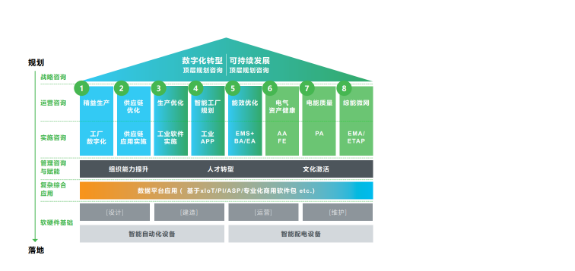

The supply chain dilemma of Star Charging is just a microcosm of the transformation of many enterprises. In the process of accelerating the dual transformation of digitalization and low-carbon, enterprises face different challenges, which also requires the dual transformation to closely follow the actual situation of the enterprise from the beginning, make comprehensive planning, and “plan before moving”. In response to this demand, Schneider Electric has innovatively launched consulting services based on its own transformation experience and advanced technology integration, combined with traditional business advantages. Through dual beams, eight pillars, and double bases, Schneider Electric empowers management consulting and complex comprehensive application from three levels: strategy, operation, and implementation. Through the integration of software and hardware that runs through design, construction, operation, and maintenance, Schneider Electric provides customized solutions for enterprises, Accelerate the digital and low-carbon dual transformation of the industry.

Consulting first, connecting the “Ren Du Er Mai” of dual transformation

Faced with the requirements of high-quality development and the “dual carbon goals”, the trend of integrating enterprise digitization and green low-carbon “dual transformation” is becoming increasingly apparent. According to a survey conducted by Schneider Electric Business Value Research Institute, the two major trends of digitalization and low-carbon are accelerating their integration. 93% of the surveyed leading enterprises have formulated a “dual line integration” strategy for digitalization and dual carbon goals, which requires technical support and industry collaboration. Small and medium-sized enterprises also need comprehensive empowerment from strategic formulation to implementation. In this process, as the first step in unleashing the value of digital low-carbon technology, consulting can help enterprises bridge the “dual pulse” of transformation: on the one hand, it can deeply explore the needs of enterprises and carry out top-level design; On the other hand, by understanding the differentiation of enterprises, we can transform it into specific paths and measures for digital low-carbon transformation.

Schneider Electric’s consulting business includes eight pillars: lean production, supply chain optimization, production optimization, intelligent factory planning, energy efficiency optimization, electrical asset health, power quality, and comprehensive energy microgrid. Combining cutting-edge technology theory and practical application, the “Eight Pillars” provide end-to-end implementation solutions for enterprise needs from the strategic, operational, and implementation levels, providing assistance for enterprise digital and low-carbon transformation.

Lean production is an effective way for manufacturing to improve efficiency and maintain market competitiveness. The application of lean production includes multiple aspects such as production line design, quality control, and inventory management. Schneider Electric Lean Consulting explores lean digital solutions and promotes the integration of OT/IT/AT/ET based on traditional lean concepts. From the specialized transformation of the lean core module to the evaluation and planning of lean systems and the construction of digital systems, Schneider Electric can combine its practical experience to create an enterprise lean management system, design the layout of factory construction, and provide related digital implementation services for customers.

In the context of dual transformation, an innovative supply chain system is an important part. Overall, Schneider Electric’s supply chain consulting starts from strategic and system consulting, including strategic level, operational level consulting, and technical level consulting solutions from strategy to implementation. Based on years of practical experience accumulated in over 200 factories and logistics centers worldwide, Schneider Electric can provide services that run through the entire supply chain from procurement, planning, production, warehousing to logistics transportation, and assist customers in achieving comprehensive transformation and improvement from business to digitalization through internal experts. Taking technology level as an example, Schneider Electric helps customers achieve supply chain management optimization through digital applications such as supplier collaboration platform, advanced planning and scheduling system APS, ERP, and supply chain control tower, focusing on procurement, planning, and logistics.

With the continuous changes in market demand, customers have higher requirements for product quality, delivery time, and cost-effectiveness. Enterprises urgently need to optimize production in order to improve production efficiency and flexibility. Industrial software is an important tool for implementing digitalization in industrial scenarios and achieving production optimization. For example, through the consultation and implementation services of factory MOM management and group integrated operation center, enterprises can achieve effective data interconnection and improve production and operation levels. Among them, the group level integrated operation center can centrally display indicators related to management, operation, and observation, and achieve horizontal comparison between factories or production lines, fully tap into the value of data, and empower enterprises for digital transformation.

Schneider Electric’s intelligent factory planning consulting integrates strategic initiatives and business scenarios, providing customers with factory level intelligent manufacturing planning and lighthouse factory planning consulting. The factory level intelligent manufacturing planning provides unified design and planning around six aspects, including park/factory construction, factory operation management, and production process optimization, and gradually advances; Lighthouse factory planning consultation can provide benchmarking analysis and case sharing, plan the construction path of lighthouse factories in a targeted manner, and effectively empower the construction. With its four major advantages in team, solution, experience, and collaboration, Schneider Electric’s digital transformation planning consulting connects the planning, application, and system three-layer architecture, achieving full domain, full level, and full link coverage, helping enterprises clarify their thinking, and achieve orderly promotion of digitalization and greening.

With the popularization of new power system related applications, balanced scheduling and energy efficiency optimization among multiple energy sources will become the focus of digital solutions to energy utilization problems. Schneider Electric can provide energy efficiency optimization consulting and use a series of energy management software, such as EMS+energy management solutions and EcoStruxure ™ Building Advisor, EcoStruxure Energy Advisor, and other energy and carbon management platforms use digital technology to connect the entire process from design, construction, operation, and maintenance, enhancing the green performance of enterprises in carbon reduction throughout their entire lifecycle.

The health of electrical assets is the cornerstone of building electrical safety, but the lifespan of electrical assets is often influenced by various factors, which can lead to significant deviations between the actual and expected lifespan of equipment. Schneider Electric provides electrical asset health consulting, including distribution system assessment consulting, analysis of changes in power system network structure, and Schneider Vision ™ EcoStruxure Asset Advisor and EcoStruxure Facility Expert from Schneider Electric provide clear guidance for ensuring the safe operation of distribution systems.

Optimizing power quality not only helps to reduce costs and improve efficiency, but also significantly enhances the competitiveness, sustainability, and safety of enterprises. Regarding power quality, Schneider Electric Consulting provides specific direction suggestions and implementation paths from three aspects: monitoring, analysis, and governance. It monitors power quality parameters in real time, timely captures dynamic changes in power quality, and through comprehensive power quality solutions such as Power Advisor, helps enterprises achieve more efficient, reliable, and sustainable power systems.

With the transformation and upgrading of the traditional energy system, integrated energy microgrid consulting will play a more important role in the new energy network. With the help of software and hardware solutions including microgrid design consulting, zero carbon project design, and EcoStruxure microgrid energy consulting, ETAP digital twin system, the overall design of the adjustment, scheduling, and optimization of the new power system will be carried out, achieving a clear estimation of the penetration rate and total energy cost of renewable energy.

Actions speak louder than words, Schneider Electric Consulting accelerates the dual transformation of enterprises

Currently, a new round of technological revolution and industrial transformation is accelerating, and digitalization and sustainable development have become topics of contemporary significance. Actions speak louder than words, guided by consulting, Schneider Electric is accelerating its penetration into various industries, helping enterprises gradually unravel their roots. Starting from the strategic, operational, and technical levels, Schneider Electric provides solutions from consulting to implementation, and conducts corresponding economic and technical feasibility analysis for each link to ensure that enterprises can scientifically and smoothly achieve the goals of digital and low-carbon dual transformation.

At a certain electronic semiconductor company, the enterprise is facing a series of challenges: traditional energy management methods are difficult to meet higher energy conservation and emission reduction goals, equipment energy efficiency status cannot be effectively monitored and managed in real time, there is a lack of detailed and accurate data and analysis as decision support, and input-output ratio is difficult to scientifically quantify. Schneider Electric has provided lean consulting to address this series of issues. Through overall lean layout planning, lean improvement and coaching, training and practice, Schneider Electric has helped companies shorten production cycle time, significantly reduce production line work in progress, standardize corporate management culture, and promote digital transformation.

In a certain energy storage and power new materials company, due to the company and factory layout in multiple locations, digital transformation is highly complex, professional, and requires high technical level. It is necessary to establish a production and quality traceability system control, information system, and unified data platform to achieve cost reduction and efficiency increase, and quickly occupy the market. Schneider Electric Planning Consulting Solution provides a group level “benchmark lighthouse factory” digital transformation blueprint and implementation path planning for the energy storage company, starting from six major architectures: infrastructure, data architecture, business architecture, and application architecture. It helps to improve data quality, achieve transparent manufacturing, improve asset utilization, unify the digital transformation strategic goals of the group and factory, and build an intelligent benchmark factory.

In a certain building materials factory project, Schneider Electric follows the methodology of “consultation first, medical treatment first, and medication later”, providing users with electrical asset consulting. Through a complete set of solutions, it helps factories that have been operating for over 20 years to improve the health of electrical assets and enhance the reliability of power operation. After relevant analysis, planning, and operation and maintenance renovation, a 30% savings have been achieved in the cost of corrective maintenance alone, and its operational safety and reliability have also been comprehensively improved.The report of the 20th National Congress of the Communist Party of China proposes that the high-quality development of the manufacturing industry is of utmost importance for China’s economic growth. It is necessary to adapt to changes in development stages, conditions, and patterns, and accelerate structural system upgrading, technological path innovation, and development model optimization with a focus on high-end, intelligent, and green development. At the same time, guided by the “dual carbon” goal, the integration of the new power system and new energy system has pushed China’s energy revolution into a new stage. Enterprises urgently need to actively optimize their energy consumption structure, refine energy and facility management, and seek more sustainable development paths. Schneider Electric Consulting provides solutions with dual beams, eight pillars, and dual bases, covering all levels from strategy to implementation. It truly meets the needs of digital low-carbon dual transformation, which is “visible”, “feasible”, and “operational”. It constructs a value cycle from planning to implementation, helping thousands of enterprises accelerate dual transformation and move towards efficient and sustainable development.

Recommended models for warehouse spare parts:

BOXER A6100M FANLESS EMBEDDED BOX PC WITH WIN-XP-PRO-ROLLS-ROYCE MARINE CPU

A-B PLC communication module 1755-A6

EMERSON Detection module A6120

EMERSON 9199-00002 A6120

EMERSON A6110

EMERSON A6110 9199-00001

EMERSON A6140

EMERSON A6140 9199-00058

EMERSON A6210

Best WOODWARD 5463-388 discrete input (48 channels)

PROCES-DATA PD621 6-IO 6-CHANNEL DIGITAL IO MODULE

Katie Neal

Dear friend, it’s nice to meet you.

kWTztzrWouJnuKYRWyboLU

Hi

vurcazkircazpatliycaz.22OoZULBMgDq

Dear friend, may I ask if there is anything I can help you with?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

zi18ty19yEy

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.