ABB collaborates with Computer Modeling Group (CMG) in underground simulation technology to provide a complete end-to-end carbon capture and storage (CCS) model.

Tracking the process of injecting carbon dioxide into underground reservoirs is crucial for the safety, feasibility, and scale of CCS projects.

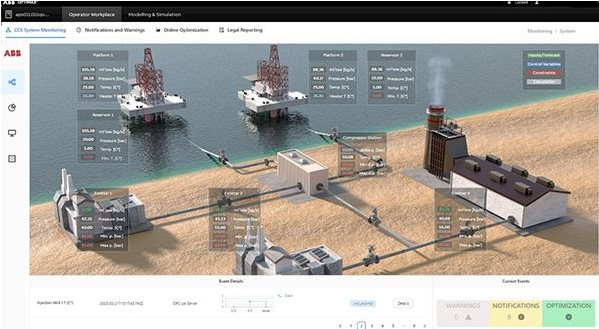

ABB’s enhanced digital twin technology can fully and transparently showcase the activities and behaviors of carbon dioxide from capture to storage.

ABB has established a partnership with Computer Modeling Group (CMG) headquartered in Canada. CMG is a global simulation technology company with over 20 years of experience in the field of carbon capture. Both parties will integrate underground simulation technology into existing digital twin technologies for the commercial operation of carbon capture and storage (CCS).

The integrated technology will be able to simulate various stages of carbon dioxide capture from the surface to the underground, whether towards the seabed or terrestrial aquifers, by allowing operators to test options in a virtual environment, reducing risks and saving costs.

Through this collaboration, ABB will leverage its Ability ™ OPTIMAX ® The energy management system combines above ground digital twin technology with underground simulation of CMG, providing comprehensive end-to-end solutions.

Brandon Spencer, President of ABB Energy Industries, stated, “Carbon capture and underground storage is a highly technical and challenging process. Providing concept validation throughout the entire CCS process is crucial for accelerating CCS adoption. Without underground simulations, cost calculations or management risks cannot be achieved, which is crucial for expanding the CCS market to support industrial decarbonization and the Paris Agreement.” Set emission reduction targets. “

Underground simulation enables enterprises to assess risks for various operational scenarios. These risks include losses or leaks caused by unexpected physical and chemical reactions between underground carbon dioxide, water, rocks, and cement, or technical failures caused by salt precipitation, such as wellbore failure.

“Both parties will collaborate to integrate the two technologies and develop new products to support intelligent and real-time operational decision-making, thereby successfully achieving large-scale carbon storage,” said Pramod Jain, CEO of CMG. “Advanced underground simulation technology is crucial for assessing and monitoring the risks of carbon dioxide injection in various operational scenarios, as well as for the safety, feasibility, and scalability of carbon capture and storage projects. We are pleased to collaborate with global innovation leaders like ABB to provide them with enhanced digital twin technology with our leading underground simulation capabilities.”

In its updated zero net emissions roadmap, the International Energy Agency (IEA) emphasizes CCS as a key factor in achieving zero net emissions targets and also emphasizes the need for CCS to make rapid progress. Although CCS has shown positive prospects, with the number of CCS projects doubling in 2021, the proportion of CCS in all decarbonization technologies is still relatively small. In order to achieve zero net emissions commitments from various countries, industrial adoption needs to increase by 120 times before 2050. However, if successful, according to McKinsey&Company data, CCS alone could potentially reduce global industrial carbon emissions by 45%.

ABB is a technology leader in the field of electrical and automation, committed to empowering a more sustainable and efficient future. ABB integrates engineering experience and software technology into a solution to optimize manufacturing, transportation, energy, and operations. With a history of over 130 years of excellence, ABB’s approximately 105000 employees worldwide are dedicated to promoting innovation and accelerating industrial transformation.

ABB Process Automation Division provides automation, electrification, and digital solutions for industrial operations, meeting a wide range of user needs from energy, water, and material supply to product manufacturing and transportation. With advanced technology and service expertise, ABB’s Process Automation Division has approximately 20000 employees worldwide dedicated to helping customers in the process industry, hybrid, and maritime industries improve operational performance and safety, empowering a more sustainable and efficient future.

CMG is a global software and consulting company that combines science and technology with profound industry expertise to address the complex underground and surface challenges of the global new energy industry. CMG is headquartered in Calgary and has offices in Houston, Oxford, Dubai, Bogota, Rio de Janeiro, Bangalore, and Kuala Lumpur.

Model recommendation:

CONSILIUM MARINE 890510 REV.8919 LOG EXTENSION BOX

EMRI AMB01-3-1891-A-R1 MOTHERBOARD

CONFOR STALECTRONIC 2000 1891-726 PCB CARD

ROLLS-ROYCE ULSTEIN MARINE DC0033A-STEPPER-MOTOR-DRIVER-891026 CIRCUIT BOARD

CONFOR STALECTRONIC 2000 1891-726

ABB AC800M PM891

ABB AC800M 3BSE053240R1 PM891

ABB 3BHE028915R0101

ABB PCD237A101 3BHE028915R0101

ICS TRIPLEX T8891C

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.