On December 18th, coinciding with the 45th anniversary of China’s reform and opening up, Foxboro China, a subsidiary of Schneider Electric, held its 40th anniversary celebration. In 1983, as one of the earliest Sino US joint ventures, Foxboro China was established in Xuhui District, Shanghai, becoming the first Sino foreign joint venture high-tech enterprise in China’s instrument and electronic industry, thus opening a new prelude to leading the vigorous development of China’s process automation industry.

Centennial precipitation, driving a leap in process automation

Foxboro is a startup enterprise that originated in Massachusetts, USA in 1908. Since the launch of its first controller in the 1920s, Foxboro has been focusing on innovation in the field of industrial control automation, providing comprehensive solutions for the manufacturing and infrastructure industries, including automation and information technology, control systems, software, services, and consulting services.

In 1983, against the backdrop of Sino US trade cooperation, Foxboro China was officially established, coinciding with a strong domestic investment in the construction of petrochemical, chemical, oil and gas process projects, and actively introducing global high-tech. In the two to three years since its establishment, Foxboro China has completed the transfer of its latest technology and products to the local market. The complete sets of system equipment products produced are used in industries such as petroleum, chemical, power, metallurgy, mining, building materials, light textiles, and food in various provinces and cities across the country. In the first 6 years of its establishment, the company’s revenue increased by 48 times and profits increased by 23 times.

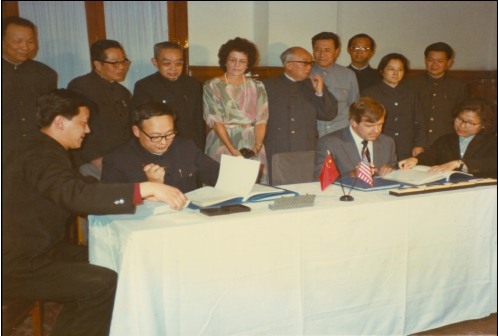

On April 12, 1982, China and the United States signed a joint venture agreement in Beijing

Juna Xin, an old employee who joined the company in 1988, witnessed the historic breakthroughs of Foxboro China. In December 1991, Shanghai Foxboro Co., Ltd. became the first enterprise in China to obtain the ISO 9001 international quality certificate, making a benchmark contribution to narrowing the gap between China’s instrument industry and even the industrial sector and the international advanced level. “After obtaining this certification, domestic enterprises from all over the country came to our side to learn from us. Many older generation experts eventually became experts in quality systems, sharing our experience and helping more enterprises obtain international quality system certification. Many of these enterprises gradually went out of China and sold their products globally,” Zhu Naxin recalled.

As a global technical expert specializing in industrial control systems, Foxboro has always been in line with local customer needs and technological trends in China, completing magnificent upgrades from hardware to software, from analog to digital, from closed to open, and from automation to digitization.

After forty years of cultivation, Foxboro’s business in China has already spread to major process industries such as chemical, refining, petrochemical, power generation, steel, cement, glass, pharmaceuticals, food, and offshore oil platforms in China. Junaxin, who has provided technical training, on-site service, sales engineer, and sales manager, has served almost all well-known enterprises in the industry in the past 35 years. He mentioned that the first batch of power plants in China, as well as the application of major refining facilities such as atmospheric and vacuum distillation, catalysis, hydrogenation, and delayed coking in the first batch of refineries, all started with the earliest application of analog DCS systems and accompanied by continuous innovation and upgrading of the Foxboro platform. With the iteration of new technologies and the upgrading and renovation of old infrastructure, Foxboro also collaborates with enterprises to innovate. For example, in the Juhua Thermal Power Plant, Foxboro collaborates with customers to develop unmanned solutions for the thermal power industry, improving the operational stability and efficiency of the plant. In addition, large local companies such as Hainan Petrochemical and Dongming Petrochemical have deepened cooperation with Foxboro China, strengthened cooperation in the software field, excavated data value, and kept up with the needs of digital transformation.

In the digital age, opening a new chapter

After being merged into Schneider Electric in 2014, Foxboro China has integrated Schneider Electric’s integrated energy management and process automation solutions, and further collaborated with industrial software, adding green and digital wings. Whether it is technological changes or localized business progress, it has ushered in a new chapter. After the launch of the new generation EcoStruxure Foxboro DCS process automation system, the Foxboro I/A Series control system, known for its reliability and future oriented industrial architecture, has been extended to integrate Triconex security technology with over 30 years of experience in functional safety and critical control applications, providing enterprise customers with a component object based engineering environment and one-stop platform services. At the conceptual level, this system almost covers a complete system from on-site instruments, to control systems, safety systems, to upper level optimization, and finally to digital factory design and operation and maintenance; At the application level, it can control and protect numerous large and complex process facilities, fully adapting to different process industries and device application scenarios.

At present, in order to continuously pursue the ultimate goal of “safe, stable, long-term, and optimal” operation of large-scale integrated process equipment, process industrial enterprises such as refining and chemical industry urgently need to transform in a series of links such as automation engineering design and delivery, instrumentation, control, operation, maintenance, equipment management, and public engineering. Based on an open EcoStruxure architecture and platform, Schneider Electric provides comprehensive process automation and digital solutions for typical process industry users, including the Foxboro DCS process automation system and full lifecycle software solutions including Foxboro process instruments, Triconex safety instrument solutions, and AVEVA industrial software, spanning enterprise design, construction The entire lifecycle of operation and maintenance.

Forty years of glory, rejuvenated to the mountains and seas. Looking back, we are grateful; Looking ahead, we are full of confidence. In the days to come, Foxboro China will continue to uphold its fine traditions of forty years, constantly innovate and develop. With the support of Schneider Electric’s energy management and digital capabilities, it will create new Chinese stories and work together with more Chinese process industry users to move towards a more efficient and sustainable future industry.

Model recommendation:

GE IC697CBL700

LAM 810-069751-114 PCBA NODE TYPE 411 CE

HE697THM160G GE

HE697THM160 GE

IC697ACC720 GE

IC697ACC722B 44A730240-G01 GE

IC697ALG440 GE

IC697BEM711 GE

IC697BME731 GE

IC697CHS770 GE