Looking back at 2023, Da Zu Robotics adheres to the original intention of “serving the people with robots”, continuously polishing its products and industry application capabilities, striving to improve customer service levels, and achieving specific results one by one to bring 2023 to a successful conclusion.

Strong product strength

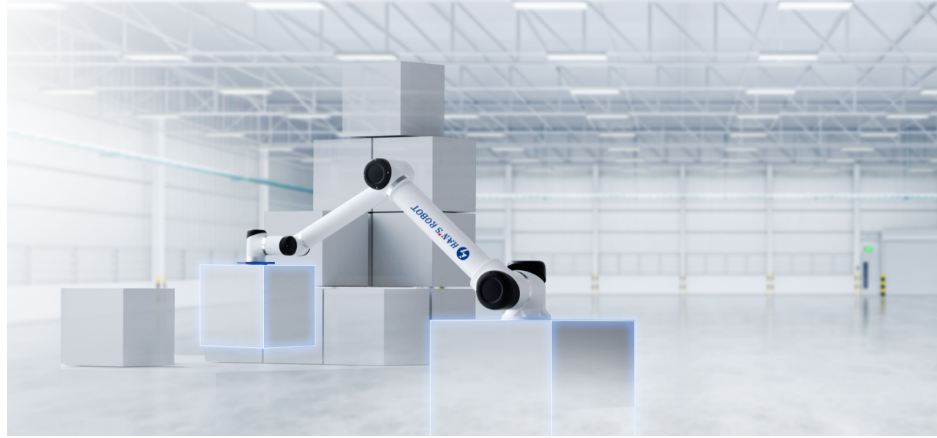

In 2023, Da Zu Robotics will continue to enrich its product matrix by launching/upgrading Elfin Pro, Elfin Ex, S series, as well as industry application solutions such as welding. With strong product strength, we meet the increasingly diverse business needs of our customers.

Official release of Elfin Pro series collaborative robots. It achieves integrated end effector force control, integrated AI vision, and real-time refresh rate control at 1000Hz. It adopts an internal wiring layout (force control/vision), and multiple parameter indicators have reached the industry-leading level.

Newly upgraded Elfin Ex series explosion-proof collaborative robots. Realize multiple explosion-proof standards, national explosion-proof certification (level Ex IIC T6 Gb/Ex IIIC 80 ℃ Db), provide four load options of 5KG, 8KG, 10KG, and 15KG, with a maximum arm span of 1300mm, and can work normally in explosive gas and dust environments.

Launch S series heavy load products. The rated load can reach up to 30KG, and the maximum working radius can reach 1800mm, which can be widely used in palletizing, assembly, and heavy load handling applications; Using the S series for palletizing can achieve up to 13 boxes/min at the fastest, making it an important tool for enterprises to improve quality and efficiency.

Upgrade the welding workstation again. Based on the Elfin Pro series as the core, Dazu Robotics utilizes technologies such as drag and drop teaching, arc tracking, and laser vision tracking to create a stable, user-friendly, intelligent, and efficient automated welding workstation (gas shielded welding), promoting the automation transformation, cost reduction, and efficiency increase in the welding field.

Strong customer service capability

In 2023, Da Zu Robotics has achieved large-scale delivery in over 30 industries, involving CNC loading and unloading, welding, screw tightening, industrial testing and many other applications. We are committed to creating collaborative robots that are more suitable for welding, palletizing, screw tightening, and spray explosion-proof scenarios, serving more domestic and foreign customers.

Application cases of ship welding. The Elfin robot is applied in the field of shipbuilding. During welding operations, the welding master can easily complete welding tasks, welding starting point, welding ending point, welding start, and other operations through the mechanical arm end button during the dragging process, which is simple, convenient, and efficient. It is easy to operate, with a lightweight design for the body, supporting drag and drop teaching, graphical programming, etc; It is more efficient, and one ordinary welder can operate four welding robots simultaneously

Application case of loading and unloading materials in gunpowder production. The customer uses Elfin Ex series collaborative robots in a completely enclosed gunpowder production workshop, replacing manual labor to automatically complete a series of operations such as gunpowder retrieval, placement, and pouring. Due to direct contact between Elfin Ex and gunpowder raw materials, customers are extremely concerned about explosion-proof performance. It achieves national explosion-proof certification, with an explosion-proof level of Ex Ⅱ C T6 Gb/Ex Ⅲ C 80 ℃ Db, meeting customer explosion-proof needs.

Application case of screw tightening. In the power battery production line, customers use three Elfin-10L machines to automatically tighten M6 screws, with a maximum torque of 40N · m. In addition to high torque, the Elfin-10L is easy to deploy and can meet efficient screw locking operations for long periods of time without the need to modify existing production lines. It supports 7 times the load-bearing torque: meeting the requirements of high torque tightening applications, with a maximum torque of 130N · m; It has excellent anti vibration performance, with almost no vibration when the robotic arm runs at full load and speed, making it precise and efficient.

Continuous market development power

In 2023, Dazu Robotics has traveled across the country and left footprints in North America, Europe, Japan, South Korea, and Southeast Asia. We actively “go out” and strive to expand our circle of friends——

This year, Da Zu Robotics has continuously entered Dongguan, Chengdu and other places to deepen industry exchanges; The first Partner Conference was held to expand the industry circle of friends; Activate the East China (Wuxi) Application Intelligent Manufacturing Center, promote sharing and mutual benefit, and strive to promote channel construction.

This year, Da Zu Robotics participated in more than 10 large-scale industry exhibitions nationwide, covering cities such as Shenzhen, Tianjin, Shanghai, and Jinan, resonating with the industry and showcasing the latest products and applications of Da Zu Robotics.

This year, Dazu Robotics has been more actively promoting its overseas layout. We have participated in multiple industry exhibitions in the United States, and have also been deeply cultivating in Russia, Japan, South Korea, Germany, Thailand and other places, bringing China’s collaborative robot solutions to the world.

Expanding influence

In 2023, we provide high-quality products and services, and have received over 20 positive reviews and honors from the industry, customers, and authoritative platforms. This is the cornerstone of our commitment to the future.

Da Zu Robotics has been listed in the “GlocalIN Top50 Technology Face of China’s Global Enterprises” enterprise map. This list is jointly released by MIT Technology Review China, DeepTech, and LinkedIn China, mainly focusing on the performance of enterprises in terms of technology and innovation strength, overseas influence, and globalization progress.

Da Zu Robotics has become one of the first batch of collaborative robot enterprises to be nominated for the “Shenzhen Intelligent Robot Application Demonstration Typical Cases (First Batch)”, and has become a “benchmark enterprise” in the field of robotics in Shenzhen. This marks the recognition of Da Zu Robotics’ technological research and development and achievement transformation capabilities in the field of collaborative robots.

Dazu Robotics has been selected for the 2023 China Future Unicorn TOP100 list. At the 7th Growth Conference of All Things in 2023 hosted by the Hangzhou government, Dahu Robotics was successfully selected as one of the “Top 100 Future Unicorn in China in 2023- Advanced Manufacturing Field”, becoming a typical enterprise in the context of “integration of industrialization and industrialization”, with “intelligence” as its main feature, deeply empowering and promoting industrial transformation and upgrading in the manufacturing industry.

Da Zu Robotics won the “2023 Welding Robot Industry Chain Pioneer Award – Advanced Technology Award”. At the welding industry forum hosted by the High Tech Robotics and High Tech Robotics Industry Research Institute (GGII), Dahua Robotics won the “2023 Welding Robot Industry Chain Pioneer Award – Advanced Technology Award”, becoming one of the key forces leading the development of collaborative welding robots.

Looking towards 2024, we will continue to maintain the “one original intention and four forces”, work together with more partners and customers, and create more celebratory milestones.

Warehouse product recommendation:

MARINE PCB ASSY PN-03956-1980732-2-7250209-REV-D MOTHERBOARD

ABB DSBB 171AM 57710256-FJ-1-2668 406-1-2 MOTHERBOARD

ABB DSBB 175B 57310256-ER MOTHERBOARD

BERGER LAHR stepper motor VRDM 566/50 LNA

A-B Impact AC Driver 1336-BDB-SP56C

A-B PLC communication module 1756-A10

A-B PLC communication module 1756-A13

A-B PLC communication module 1756-A17

ELEKTRONIX AS ENIX-2000-T56-S FANLESS COMPUTER

vibro-meter 204-656-000-1301

Vibro-meter UVC656 13-01

KOLLMORGEN CB06560 PRD-B040SAIB-62

KOLLMORGEN CB06560 PRD-B040SAIB-62

KOLLMORGEN CB06561 PRD-B040SSLZ-62

GM INTERNATIONAL D1031D PROXIMITY DETECTOR REPEATER

GM INTERNATIONAL D1031QB PROXIMITY DETECTOR REPEATER

GROSS FUNK SE889-T23R61-03226GV1 RADIO REMOTE CONTROL RECEIVERS

GROSSFUNK SE889-T23R61-03226GV1 RADIO REMOTE CONTROL RECEIVERS

GUNTNER CDB34.003.C2.5-OLG-SOFT-V220.50-07 DRIVE

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?