With the development of the logistics industry towards informatization and intelligence, the application of automated three-dimensional warehouse, the core equipment of Logistics automation, is becoming more and more extensive. How to operate equipment and systems safely and stably has become an increasingly important and complex technical topic.

Automated Stereoscopic Warehouse (AS/RS) is a complex automation system composed of automated storage and retrieval equipment such as three-dimensional shelves, lane stacking cranes/shuttle cars, inbound and outbound tray conveyor systems, communication systems, automatic control systems, computer monitoring systems, computer management systems, and other auxiliary equipment. Its safe and stable operation is the foundation for ensuring its efficient performance.

The first “defense line” of automated three-dimensional warehouses

In the design and construction process of automated three-dimensional warehouses, in addition to considering the efficiency of equipment, its safety cannot be ignored. By taking necessary safety protection measures, to avoid or reduce damage to equipment and goods caused by personnel operation errors or equipment operation deviations, as well as personal injury to relevant personnel.

Safety protection measures are an essential part of automation systems stipulated by various safety regulations. Safety fences and safety doors are the first “line of defense” of protection measures in automated three-dimensional warehouse systems, and there are clear requirements in various regulations.

Pilz’s PSENmlock safety door system provides safety interlocking and safety protection locking for personnel and process protection, and can be used for applications with the highest safety level PL e and below. Due to the dual channel operation of the protective locking device, this switch is particularly suitable for machines with dangerous overtravels that require a safety protection locking level of PL d or PL e. With a locking force of up to 7500N, the PSENmlock safety door system can prevent accidental opening of protective devices, ensuring maximum safety. The PSENmlock door handle module also provides door handles with integrated actuators and integrated escape release devices. The yellow door handle (outside) allows maintenance personnel to easily open the safety door from the outside. When maintenance personnel accidentally fall into a hazardous area, the escape release function of PSENmlock can be activated through the red door handle (inside) to escape from the hazardous area.

The PSENmlock door handle module is suitable for installation on various mechanical safety doors and can perform tag out and lock out operations. The combination of PSENmlock and Pilz’s control technology is a comprehensive solution for monitoring and activating protective locking devices!

Protective “sharp tools” at human-computer interaction interfaces

According to GB16655-1996 “Basic Requirements for the Safety of Integrated Manufacturing Systems in Industrial Automation Systems”, effective protective measures need to be added to the logistics equipment and manual operation interfaces in the automated three-dimensional warehouse system, and isolation barriers should be set up at the boundaries of the work area outside of human-machine interaction to prevent personnel from bypassing safety protection and entering the internal area of the warehouse.

Using PSENopt and PSENopt II Light curtain in human-computer interaction interface can effectively and economically protect the safety of employees and assets. When Light curtain is used together with shielding sensor, it can distinguish between people and objects, and is an ideal choice for production processes requiring active intervention.

The PSENopt and PSENopt II series products have a wide range of optional models, ranging from finger protection to body protection, covering the vast majority of application scenarios, whether it is narrow space applications or extended functions such as shielding, blanking, or cascading.

The “Soul” of Automated Three-dimensional Warehouse

The soul of automated three-dimensional warehouses lies in control systems, which are divided into safety control systems and standard control systems. The security control system provides a safe and reliable means of protection, which can detect and prevent the unsafe state of equipment to the greatest extent, and protect the safety of personnel and equipment.

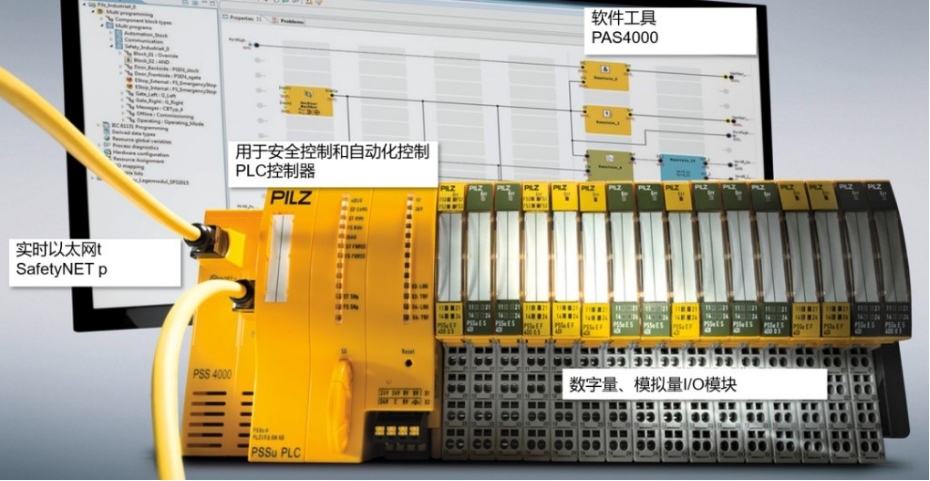

PSS4000 integrates security control and standard automation control functions in a system, which is widely used and can easily and flexibly implement security and automation applications of any scale. The PSS4000 safety PLC adopts a redundant multiprocessor structure, and the system will compare the data on the processor in real-time during operation. In case of any abnormality, it will immediately switch to the safety protection state to achieve protection for equipment and personnel. Safetynet_ P The security bus is suitable for large-scale and distributed security control systems. It is a security communication protocol developed based on Industrial Ethernet. It adds a series of connection detection, address detection, time detection, CRC redundancy verification and other measures on the basis of Industrial Ethernet.

PSS4000 is the perfect choice for large-scale automation projects