Description

The lithium-ion battery system mainly consists of battery, power conversion system (PCS), energy management system (EMS), battery management system (BMS) and other electrical equipment. The secondary BMS design has multiple monitoring of system status and hierarchical linkage. Relays, fuses, circuit breakers, and BMS form a comprehensive protection system that integrates electrical safety and functional safety.

System components

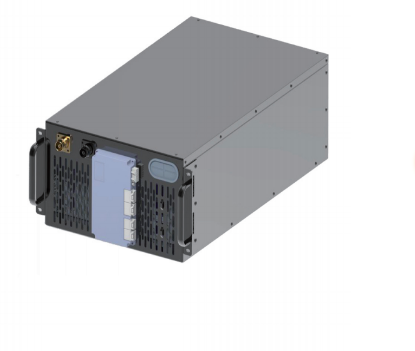

Lithium battery module

The main components of the system are composed of a battery module composed of safe, efficient, and long-life lithium iron phosphate cells connected in series, and a battery cluster composed of multiple modules connected in series.

Battery management system

The core components of the system effectively protect the battery from overcharging, discharging, overcurrent, etc., while balancing the battery cells to ensure the safe, reliable, and efficient operation of the entire system.

Monitoring system

System operation data monitoring, operation strategy management, historical data recording, system status recording, etc

System characteristics

Safe and reliable

First line factory home appliance core, intelligent air-cooled design, long service life. Module and battery cluster secondary BMS design, multiple status monitoring, and three-level electrical protection system.

Efficient and convenient

High energy systems have high energy density, stable and reliable performance, long service life, modular design, and are easy to maintain, manage, and expand.

Active balance

3A active balancing to overcome the impact of a single capacitor on system capacity. The balancing accuracy is less than 2%, and the balancing capacity reaches 10% of the rated output.

Cost optimization

Small size, light weight, saving space and cost. Long cycle life, low failure rate, reducing 0&M investment.

Cell

The lithium battery system adopts a 3.2V 280Ah high-energy lithium iron phosphate battery cell with a square aluminum shell design, reducing the possibility of mechanical damage to the cell surface and internal damage to the cell, and improving safety performance. Product. A membrane shaped explosion-proof valve is installed on the battery cell, ensuring that in any extreme situation (such as internal short circuit, battery overcharging and discharging, etc.), a large amount of gas that quickly accumulates inside the battery cell can be eliminated. Discharge through explosion-proof valve to improve safety.

module

The battery module consists of 12 3.2V 280Ah lithium iron phosphate cells in parallel with 12 series (12S1P) to form a 38.4V 280Ah battery module. The module is equipped with a built-in BMU system, which collects the voltage and temperature of each battery cell, and conducts balanced management of the battery cells to ensure the safe and efficient operation of the entire module.

How is the early warning of the security system implemented?

BMS Level 3, Level 1 warning, Level 2 alarm power down, Level 3 power off; Temperature, smoke, and combustible gas detection, using propane for fire extinguishing, as well as remote and on-site alarms, far-infrared video monitoring and recording.

How is ultra-high voltage converted into power supply voltage?

Within the enterprise, the ultra-high voltage of the city power is converted into power supply voltage through substations or transformers, providing normal equipment usage and energy storage devices.

Warranty issues, cycle times issues, how many cycles can a normal battery cycle?

The warranty period is 5 years, with the first three years being free, and the second two years being charged for accessory costs and travel expenses; The normal cycle life of the battery is 6000 times

The normal cycle life of the battery is more than 6000 times, and it can be used for more than 15 years after charging and discharging once a day, and for more than 8 years after charging and discharging twice.

How to maximize the efficiency of two charges and two discharges?

The valley peak and flat peak (fully charged and discharged) maximize system utilization.

What are the configuration facilities for storage cabinets?

It consists of a battery pack, battery management system BMS, energy storage converter PCS, energy management system EMS, fire protection system, monitoring system, and other related auxiliary systems.

The system, monitoring system, and other related auxiliary systems are small in size, large in storage capacity, and resistant to high and low temperatures.

What are the benefits of energy storage cabinets?

(1) Cut peak and fill valley, utilize the difference in peak and valley electricity prices, and save over 60% of electricity bills.

(2) Not affected by power outages or restrictions, and not affecting normal production.

(3) State subsidies and enterprise income tax equipment credits.

(4) Emergency preparedness and standby.

(5) Reduce carbon emissions, connect to the grid for operation, benefit all, make data public and transparent, and monitor and calculate the national power grid.

(6) Lithium iron phosphate batteries will not cause thermal runaway, explosion, or fire.

What is the required floor area for energy storage cabinets?

The installation of 100kWh to 215kWh indoor energy storage cabinets covers an area of 4m and weighs approximately 2.5T. The three side side design occupies a small area. The outdoor cabinet is designed according to fire prevention and temperature control requirements, and can be placed in an open space outside the power distribution room as required.

Is there an annual maintenance fee for the storage cabinet?

Roughly calculated, for every 1 megawatt hour, the maintenance cost is about 10000 yuan. The maintenance cost is relatively low in the first 3-5 years, and after five years, the maintenance cost is about 0.5-2% of the cost of the entire equipment; (Investing in a 1WKH energy storage cabinet, with an investment cost of approximately 1.45 million yuan, and maintenance costs of approximately 7000 to 28000 yuan after five years, depending on the degree of aging on site)

Reviews

There are no reviews yet.