Siemens’ HEEDS AI Simulation Predictor solution can help businesses leverage the advantages of digital twins and achieve product optimization through built-in accuracy aware artificial intelligence technology

Based on the knowledge and experience accumulated in historical simulation research, deliver innovative high-performance designs faster

The Simcenter Reduced Order Modeling solution utilizes high-precision simulation or test data to train and validate AI/ML models, enabling them to make predictions within a fraction of a second

Siemens Digital Industrial Software recently launched two innovative solutions – HEEDS ™ AI Simulation Predictor software and Simcenter ™ Reduced Order Modeling software is designed to help engineers overcome the complex challenges faced by today’s manufacturing industry, enabling fast, accurate, and efficient predictability.

The engineering team can now leverage Siemens’ HEEDS AI Simulation Predictor solution to tap into the potential of artificial intelligence driven predictive modeling and explore new opportunities in industrial design together with other industrial software from Siemens Xcelerator.

Advantages of HEEDS AI Simulation Predictor solution:

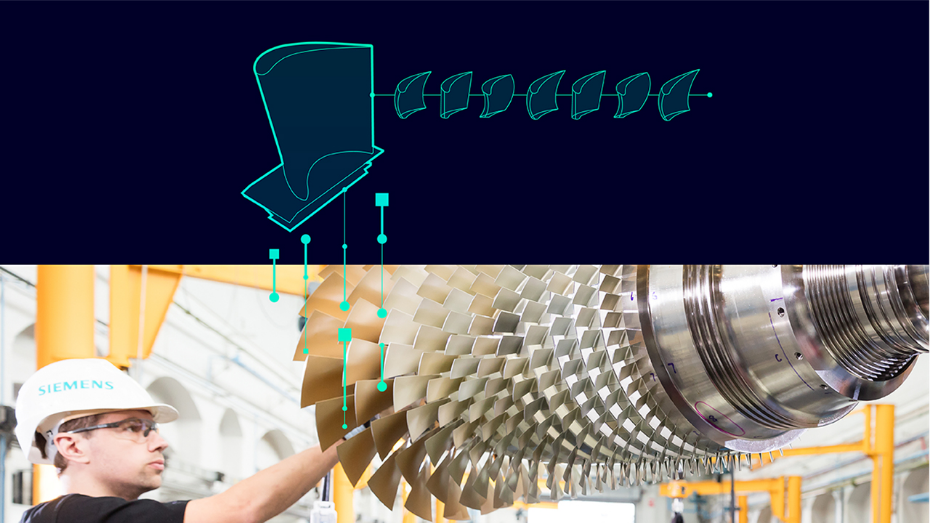

Precision optimization of products: The HEEDS AI Simulation Predictor solution utilizes artificial intelligence technology with built-in accuracy awareness to help enterprises fully leverage their digital twin capabilities and perform precise fine-tuning and optimization of products.

Realize faster and more innovative design: By mining the accumulated knowledge from historical simulations, help engineering teams quickly achieve design innovation and significantly shorten time to market.

Addressing the Challenge of Artificial Intelligence Drift

AI drift is one of the rigorous challenges faced by AI simulation, where models may experience inaccurate inference when facing unknown design spaces. To solve this problem, the HEEDS AI Simulation Predictor software introduces artificial intelligence with accuracy awareness, which can actively self verify predictions and help engineers carry out accurate and reliable simulations in practical engineering application scenarios.

Behnam Nouri, team leader of Siemens Energy Engineering and Platform Design, stated: With the help of the HEEDS AI Simulation Predictor software, Siemens Energy has achieved significant improvements in various components of gas turbines and effectively improved thermal mechanical fatigue prediction. We are now able to process approximately 20000 design components in 24 hours, increasing the service life of components by 20%. This allows us to fully describe the limitations of the existing design space and create more efficient turbine engines “Or technology has now successfully saved us over 15000 hours of computing time.”

Simcenter Reduced Order Modeling, launched simultaneously by Siemens, is a solution that utilizes high-precision simulation and testing data to train and validate AI/ML models. Based on trained and validated models, engineers can perform predictions in a fraction of a second.

Advantages of Simcenter Reduced Order Modeling solution:

Speed and accuracy: Simcenter Reduced Order Modeling software helps engineers quickly obtain predictions and make critical decisions by using high-precision data, which requires less time compared to traditional methods.

Predictive performance: By training AI/ML models based on comprehensive datasets, engineers can obtain robust, reliable, and trustworthy insights, helping them eliminate common AI drift problems.

Jurgen Dedeurwaerder, a simulation engineer at Plastic Omnium, stated: The Simcenter Reduced Order Modeling solution can help us improve the speed of simulation models, allowing detailed fuel cell device models to run faster than real-time while maintaining the same level of accuracy as complete system models. We can now increase the speed of models in the development and testing stages of the loop controller, reducing the entire development cycle by about 25%. At the same time, this solution also provides us with a way to Distribute the model to internal and customer teams in a cost-effective, IP protected manner to enhance products and processes, and deliver better quality products to end usersJean Claude Ercolanelli, Senior Vice President of Siemens Digital Industrial Software Simulation and Testing Solutions, stated: HEEDS AI Simulation Predictor and Simcenter Reduced Order Modeling have achieved a true breakthrough in the field of simulation technology, enabling our clients to fully leverage the effectiveness of AI simulation and improve the speed, accuracy, and robustness of their design space exploration. Now, clients can not only apply these innovative technologies to new projects, but also utilize decades of accumulated historical simulation data to propose comprehensive solutions for existing projects New insights. “

Model recommendation:

BEMAC UZUSHIO TYPE-UZFPD15-08G00647 MARINE COMPUTER SYSTEM

A-B I/O module 1785-ME64

JRCS SGD-640-X4G-3 15 INCHES LCD DISPLAY

JRCS SGD-640-X4G-2A 15 INCHES LCD DISPLAY

STEIN SOHN VISTA AUTOMATION TYPE-070640-F503006A-XAS-EXTENSION-ALARM-SYSTEM CONTROL PANEL

RHEINTACHO MESSTECHNIK GMBH 5750

ABB CVC750AE101 3BHB005171R0101

GE VMIVME-7750-734001 350-027750-734001 K

Your article helped me a lot, is there any more related content? Thanks!