Description

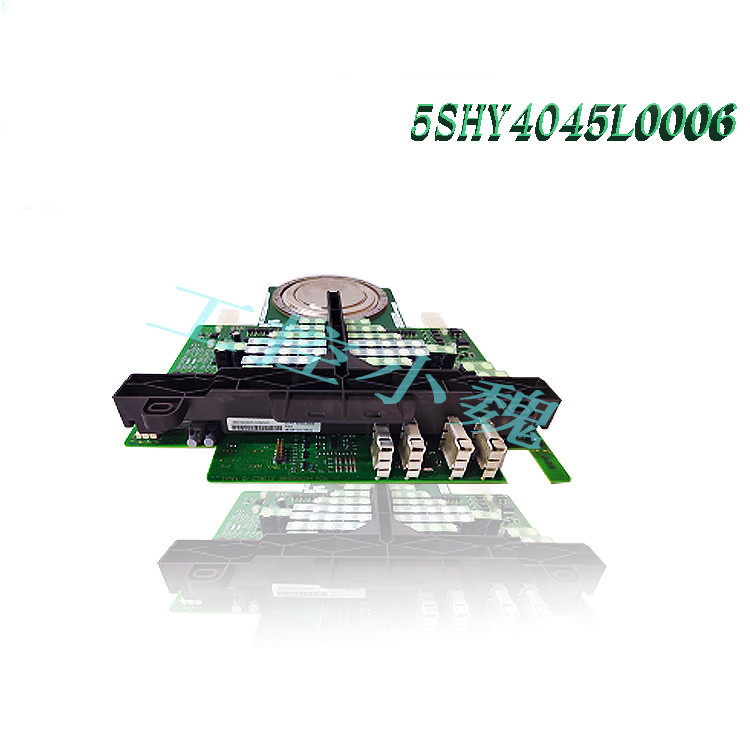

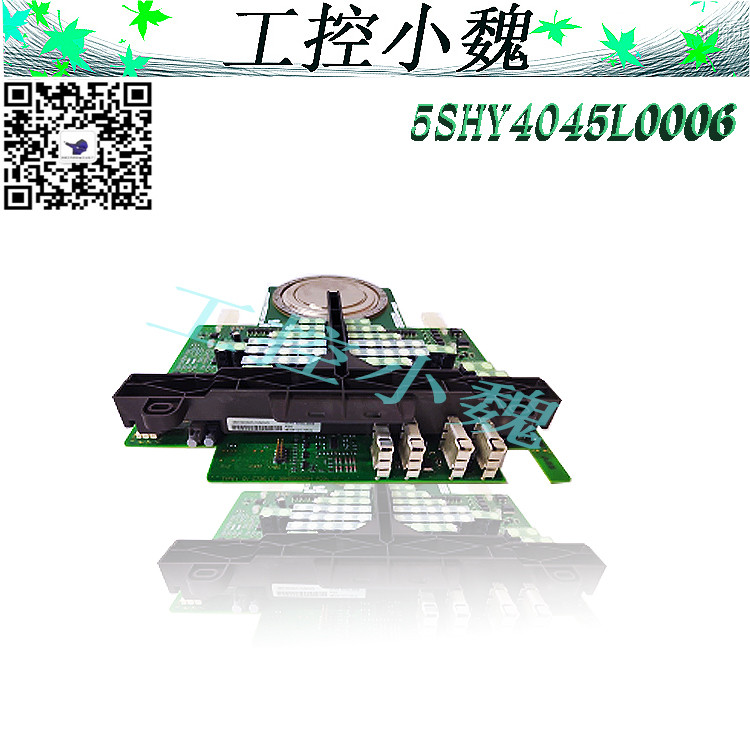

Detailed information for: 3BHB030310R0001This page contains technical data sheet, documents library and links to offering related to this product. If you require any other information, please contact us using form located at the bottom of the page.Print… Print to Pdf… Data Sheet Downloads3BHB030310R0001 General Information Product ID:3BHB030310R0001 ABB Type Designation:4500V, 91mm, 5SHY 4045L0006 Catalog Description:4500V, 91mm, 5SHY 4045L0006; IGCT MODULE Long Description:4500V, 91mm, 5SHY 4045L0006 Categories Parts & Services » Drives » Services » Spares and Consumables » Parts Ordering Country of Origin:United States (US) Czech Republic (CZ) Switzerland (CH) Finland (FI) Customs Tariff Number:85413000 Invoice Description:IGCT MODULE Made To Order:No Minimum Order Quantity:1 piece Order Multiple:1 piece Quote Only:No Selling Unit of Measure:piece Dimensions Product Net Weight:3 kg Package Level 1 Units:1 piece Technical Frame Size:Spare_Parts Additional Information Product Name:IGCT MODULE Classifications UNSPSC:32111700 Environmental WEEE Category:Product Not in WEEE Scope

ABB helped Shandong Nanshan Aluminum to further improve product quality and efficiency by providing a complete range of tailored automation solutions for China’s first 3-stand Tandem Cold Mill (TCM) by Shandong Nanshan Aluminum Company.

Shandong Nanshan Aluminum Co Ltd

Shandong Nanshan Aluminum Co Ltd was established in 1993. At present, the company has many large subsidiaries and branches such as electricity, alumina, electrolytic aluminum, aluminum section, light alloy, etc., which form an industrial chain of “electricity—alumina—electrolytic aluminum—aluminum deep processing”, with strong competitive power.

Major challenges

The mill has a capability to reduce the thickness up to 60% in the 1st stand and maximum up to 89% in one run. To fulfill the high demands, the following key technology issues have been taken into account:

Selection of optimal control concept with bump-less switch over according to mill mode of operation and available sensors

Decoupling between Roll gap, Mill drive and Flatness Control to eliminate interactions between the loops

ABB scope of supply and services

ABB has delivered the complete drive and control system for the new 3-stand 6-high aluminum tandem cold mill. ABB’s scope of work executed in project management, basic and detail engineering, In-house test, supervision for erection, commissioning and optimization.

What has been achieved?

For the main drives, ABB has used the most modern AC medium-voltage drive system “ACS6000” with unique Direct Torque Control (DTC) and ABB’s IGCT components. The drive system controls torque and speed, so that it remains fast and accurate under all operational conditions. These are important preconditions for all other technological control tasks, like thickness, flatness and tension control that results in the increased quality of the final product.

The new automation technology is based on the state-of-the-art ABB 800xA platform and, in addition to the peripheral units, I/O and communication modules, includes a set of high-tech controllers of the type AC 800PEC. The controller is used in all applications for rolling mills and processing lines, including technological control, drive control, plant control functions and auxiliaries. A Client / Server architecture with operator terminals was installed for process visualization and plant operation. The programming languages for the system conform to IEC 61131-3. Moreover, ABB’s migration philosophy ensures long lasting life cycle support. The advance control system applies various technological methods for controlling thickness, mass flow, tension, speed, flatness, etc.

For hardware-in-the-loop test, a mathematical process model and simulation was used in pre-commissioning of the rolling mill, which simulates the complete Tandem Cold Mill (TCM) with respect to the normal rolling mill operation from strip threading, normal operation up to tailing-out. This software enables pre-tuned control loops and secures a very smooth startup of the coil production.

The production management system implemented by ABB has different functions as following:

Order planning and management

Material tracking

Roll management, including data exchange to roll change robot and roll grinder

Quality data management

Product and production reports

Self-adapting mathematical model-based pass scheduling and set-up calculation

Interface to level 1, level 3 and high bay storage

In this project, self-adapting mathematical model-based pass scheduling and set-up calculation has been initiated automatically on the basis of the coil, roll and adaptation data as well as the operator trimming values and a product dependent rolling practice. Adaptive models for roll force, torque, forward slip, roll and strip temperature, thermal crown, mill stand module, roll bending and wear, are used to predict the expected process behavior in all phases of rolling and secure optimal set-up values. More than 200 set-points and control parameters are preset by the

ABB solutions in cold rolling millsIncreased productivity and product quality with innovative solutions

The quality of cold rolled flat products is a decisive factor for the metals industry. The ABB process and power system, designed for cold rolling mills, offers advanced solutions for quality control, and analysis to meet your cold rolling steels needs in terms of thickness and flatness tolerances as well as surface characteristics.

With more than 100 years of metal process experience and proficiency and knowledge obtained from over 800 cold rolling projects, ABB is the ideal partner for projects within rolling mills including processing steel, silicon steel, stainless steels, titanium, as well as non-ferrous metals. ABB supplies a full range of products from reliable instrumentation and control systems, advanced drive technology and power management through to forward-looking technological control solutions for specific functions and turnkey projects, including:

Tailor made solutions for greenfield projects and revamps

Full scope of electrical and automation equipment ‘made by ABB’ from the drive through to production management, via process automation

Centers of excellence with experienced engineers available in many countries

Service structure for products and field services available all over the world

model for each coil.

Model recommendation:

ABB 5SHY3545L0014 3BHB020720R0002

.jpg)

Reviews

There are no reviews yet.