Description

Many products are not yet on the shelves. Please contact us for more products.

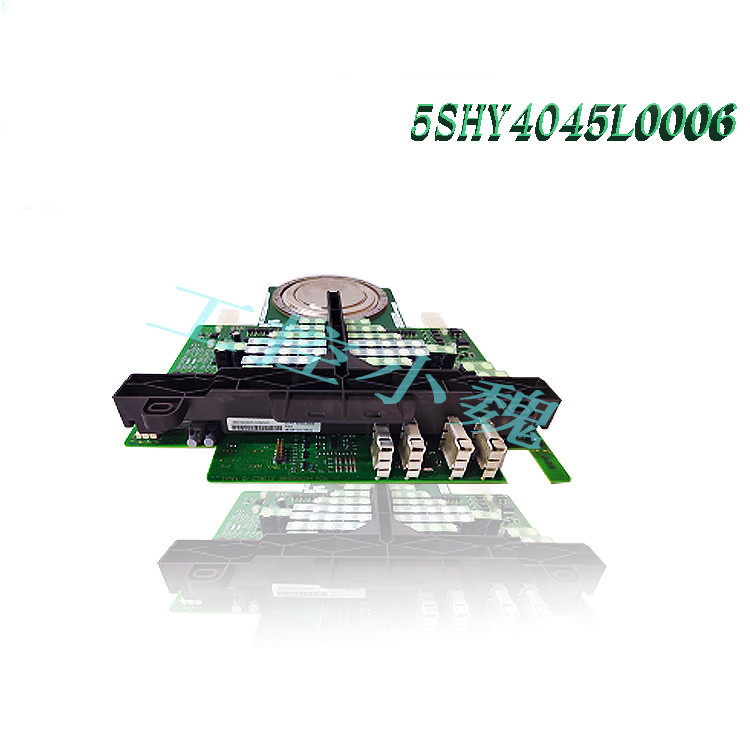

If the product model is inconsistent with the display picture, the model shall prevail. Please contact us for specific product pictures, and we will arrange to take photos in the warehouse for confirmation.

We have 76 shared warehouses around the world, so sometimes it may take several hours to return to you accurately, please understand. Of course, we will respond to your concerns as soon as possible.

3BHE009681R0101 Other names:

Integrated gate-commutated thyristor 3BHE009681R0101

3BHE009681R0101 inverter module

Medium and high voltage inverter module 3BHE009681R0101

This module belongs to ABB’s IGCT (integrated gate-commutated thyristor) series, which combines the high blocking voltage and low conduction loss characteristics of GTO (gate turn-off thyristor) with the high-speed switching characteristics of IGBT (insulated gate bipolar transistor). It is mainly used in medium and high voltage inverters, power systems (such as 100MVA transformers) and industrial drives (such as 5MW drives). It is suitable for occasions requiring high power control and regulation.

Integrated technology advantages

Adopting IGCT (Integrated Gate Rectifier Thyristor) technology, combined with the low conduction loss of GTO (Gate Turn-off Thyristor) and the stable turn-off capability of transistor, it supports high-frequency switching (500Hz-40kHz) and is suitable for medium and high voltage inverter scenarios.

Non-buffer circuit design: No additional buffer capacitor or diode is required, simplifying the circuit structure and improving system reliability.

Thermal management and scalability

The module is directly mounted on the heat sink through pressure contacts to optimize the heat conduction efficiency.

Supports series or parallel expansion, with a maximum capacity of up to 100MVA, suitable for large-capacity power electronic equipment.

Control interface

Electrical isolation and anti-interference are achieved by transmitting the trigger signal through optical fiber.

Integrated control unit, only external power supply is required to drive, supporting fast switching response (switching frequency up to 40kHz).

Technical support

Improved shutdown performance: Enhance the safe operating area of IGCT through uniform switching.-1.jpg)

Dynamic avalanche limit: Improve the reliability and durability of the equipment.

High-frequency application expansion: supports switching frequencies in the kHz range, suitable for high-frequency application scenarios.

Electrical performance

Voltage level: adapted to medium and high voltage scenarios, supports series expansion to 100MVA applications.

Switching frequency: typical value 500Hz, short pulse train mode can reach 40kHz, taking into account both efficiency and dynamic response.

Loss optimization: adopts anode transparent emitter technology, dynamic loss is reduced by about 50% compared with traditional devices.

Structural design

Integration: built-in gate drive unit and status monitoring circuit, optical fiber transmission control signal, strong anti-interference.

Heat dissipation method: press-fitting process directly fits the heat sink, with both electrical contact and heat conduction functions.

Typical application scenarios

Power system

It has been commercially deployed in 100MVA transformers to improve grid stability and energy conversion efficiency.

Applicable to scenarios such as flexible direct current transmission (HVDC) and static VAR compensation (SVG).

Industrial Drive and Frequency Conversion

Integrated in ABB ACS1000/ACS6000 series medium voltage inverters to drive 5MW industrial motors.

Supports fast switching of electric/braking modes to optimize energy feedback efficiency.

New Energy and Energy Storage

Applicable to photovoltaic inverters and energy storage converters (PCS) to achieve efficient DC-AC conversion.

Medium and high voltage frequency conversion drives

Used for motor speed regulation, compressor control, etc., supporting 300kVA to 10MVA single-machine converters without additional series/parallel connection.

Power System Control

Active Rectifier Unit (ARU): In ABB ACS6000 and other inverters, bidirectional energy flow and DC voltage stability are achieved.

Static VAR Compensation (SVG): Optimizes power factor of power grid and improves system stability.

Industrial Special Power Supply

Adapts to the special power supply needs of metallurgy, chemical industry and other industries, and supports high-frequency design to reduce the filter size.

Summary

The ABB 3BHE009681R0101 IGCT module is designed for high-voltage and high-power scenarios. It combines the low-loss characteristics of GTO and the fast switching advantages of IGBT, and is suitable for inverters, power systems and industrial drives. Its high reliability, modular design and mature ecological support make it an ideal choice to replace traditional thyristors (SCRs) and high-voltage IGBTs.

All products on this website are special products, and market prices have been fluctuating.

The specific quotation is subject to customer service, because the product is a new product and the price is not real.

Please confirm the model and product, price and other detailed information with customer service before placing an order. The website has been used.

New ones are on sale, please contact customer service for communication.

Model recommendation:

ABB 5SHX1960L0006

ABB 5SHX1960L0006

ABB 5SHX1960L0006

ABB 5SHX1960L0006

ABB 5SHX1960L0006

5SHX1060H0003

5SHX1060H0003

5SHX1060H0003

5SHX1060H0003

5SHX1060H0003

5SHY3545L0014

5SHY3545L0016

5SHY3545L0014

5SHY4045L0003

5SHY4045L0003

5SHY4045L0003

5SHY4045L0003

5SHY3545L0003

5SHY3545L0003

5SHY3545L0005

more……

-1-100x100.jpg)

-300x300.jpg)

Reviews

There are no reviews yet.