Description

Important User Information: Please read this document and other resource sections regarding installation, configuration, and before installing, configuring, operating, or maintaining this product, please operate this device first. Users are required to be familiar with all applicable regulations, laws, and standards, as well as installation and wiring instructions. Activities such as installation, adjustment, putting into use, assembly, disassembly, and maintenance need to be carried out by appropriately trained personnel in accordance with applicable practical norms. If the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be damaged. In no case shall Rockwell Automation be responsible for indirect or consequential damages caused by the use or the application of the equipment. The examples and charts in this manual are for illustrative purposes only.

Due to the many variables and requirements related to any specific installation, Rockwell Automation, Inc. does not assume any responsibility or obligation based on the actual use of examples and charts. Rockwell Automation Co., Ltd. assumes no patent liability for the use of information, circuits, equipment, or software, as described in this manual. Reproduction of all or part of this manual without written permission from a limited liability company is prohibited. In this manual, if necessary, we will use annotations to inform you of safety precautions. Rockwell Automation recognizes that some of the terminology currently used in our industry and in this publication is no longer consistent with the movement of inclusive language in technology. We are actively working with industry peers to find alternative solutions to such clauses and making changes to our products and content. Please forgive us for the changes made in our content while we implement them. Labels can also be placed on or inside the equipment to provide specific preventive measures. The following icons may appear in the text of this document. Warning: Identify information about practices or situations that may cause explosions in hazardous environments, which may result in personal injury, property damage, or economic loss. Attention: Identify practices or situations that may result in personal injury or property damage, such as information damage or economic losses. Precautions help identify hazards, avoid them, and recognize the consequences. Identifying important information that is crucial for successful application and understanding of the product. Electric shock hazard: Labels may be on or inside the device, such as drives or motors, to alert people to the potential presence of voltage. Burn hazard: Labels may be placed on or inside the equipment, such as drives or motors, to alert people that the surface may reach dangerous temperatures. Arc flash hazard: Labels may be placed on or inside equipment, such as motor control centers, to alert people to potential arc flashes. Arc flashing can cause serious injury or death. Wear appropriate personal protective equipment (PPE). Focusing on all safe work practices and the regulatory requirements for personal protective equipment (PPE) identifies useful information that helps make the process easier to implement or understand. Like the Kinetix 300 hard drive, the Kinetix 5100 hard drive PR mode provides index control operations (homing and indexing) through digital input by executing pre configured motion commands. On the Kinetex 5100 hard drive, you can use the KNX5100C software to configure up to 99 different command types, with a specific command for homing. The Position Register (PR) command contains an index, but it has additional capabilities. In PR mode, these different command types include homing, point-to-point position command, speed command, jump command, write command, and arithmetic operation command. Except for arithmetic operations, the attributes and corresponding data of each PR command are set through KNX5100C software. On the Kinetex 300 hard drive, the motion commands DI.StartIndex, DI.DefineHome, and DI.IndexSelect0 to DI-Index Select5. In Kinetex 5100, the motion commands are from DI.CTRG and DI.POS0 to DI.POS6. When using the digital I/O control panel in KNX5100C software, it provides: start and stop index commands, start and stop resets, enable or disable drives, and index execution monitoring digital input wiring.

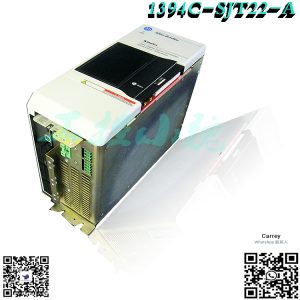

Popular models:

Reviews

There are no reviews yet.