Description

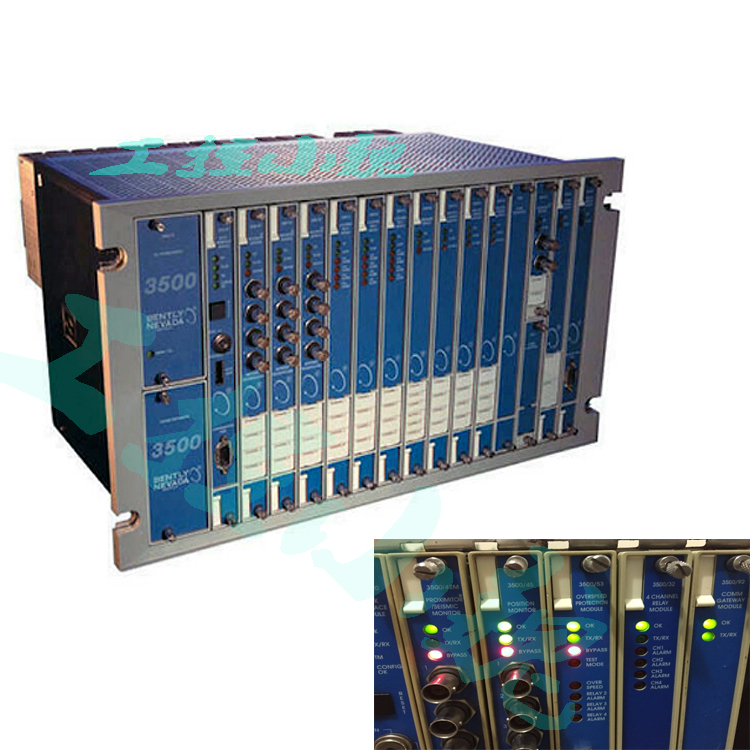

| brand; | BENTLY |

| model; | 330180-X1-CN |

| QQ email; | xiongbacarrey@qq.com |

| weight; | 11kg |

| Specifications; | 12cm |

| Telephone; | 86 18030177759 |

| contacts; | Carrey |

| address; | Xiamen Xiongba E-commerce Co., Ltd., Unit 2009, Luling Road, Siming District, Xiamen City, Fujian Province |

| Personal official website | https://www.weikunfadacai1.com |

| Properties: | Purpose Rack Interface, PLC Control, Analog Input, Motor Mechanical Protection, Voltage Sensing, System Control |

| Specification: | medium, 20 * 15 * 16, 20 * 30 * 16, 10 * 16 * 23 |

| Features: | high security, high efficiency, high security, high precision, safe, efficient and durable, secure encryption, stable and efficient, stable and energy-saving |

| System environment: | normal temperature, high temperature resistance |

| Operating system: | 3500 security system, ISI system, PLC system

Powerful and programmable system |

| Applicable industry: | power plant steel plant cement plant ship papermaking |

| Service advantages: | after-sales guarantee and sufficient supply |

| Express: | Shunfeng/Deppon Express Land |

| Sales scope: | worldwide |

| Output frequency: | 50/60 |

| Product certification: | original factory certification

Model OK |

| Working voltage: | 24Vdc/120Vac |

| Color: | natural standard color |

Description

The 60M100 Condition Monitoring System continuouslymonitors wind turbine machine trains using sophisticatedsignal processing algorithms and machine operating states.The 60M100 Monitoring System, as a part of condition- basedmaintenance,

detects defects months in advance of apotential failure.Depending on the size of your wind farm, early detection canreduce outages and production loss, saving you hundreds ofthousands to millions of dollars per year in lost revenue. Withthe advanced knowledge provided by the 60M100, you canschedule maintenance outages and crane operations inadvance, reducing maintenance costs.The 60M100 Monitor can be used in several configurations:As an independent, standalone condition monitoring.jpg)

system.A networked, distributed collection of inter-operatingsystems.As an integrated part of a machine OEM’s control andinstrumentation package.The 60M100 monitor includes features and advantages notprovided in other systems. The monitor systems have allfunctionality required for condition monitoring of wind

turbine machine trains including signal conditioning,alarming, configuration, speed inputs, and control system

communication.The system components include: 60M100 Monitor, Adapt.windsoftware, Transducers and cables. Sophisticated signal processing algorithms extract dozens ofmeasurements and health indices from each accelerometerpoint and can be custom tuned to specific bearing and gear

Sophisticated signal processing algorithms extract dozens ofmeasurements and health indices from each accelerometerpoint and can be custom tuned to specific bearing and gear

box characteristics.The 60M100 monitors 150 static variablesproducing high resolution waveform data and

trendllines.The 60M100 is a powerful and versatileCondition Monitoring system that providesbasic monitoring functions and advancedsignal processing and rules in a compact,

robust unit. The module conditions the inputsignals to make various measurements andcompares the conditioned signals with user-programmable alarms.Capable of taking input from different sensortypes, the 60M100 System can support up to 12dynamic channel inputs,  two Keyphasorsignals, and digital communications. Channel 1through channel 10 interface with 2: -wire ICPtype accelerometers. Channels 11 and 12 can beconfigured to interface with either 2-wire ICPtype transducers or 3-wire proximity probes.

two Keyphasorsignals, and digital communications. Channel 1through channel 10 interface with 2: -wire ICPtype accelerometers. Channels 11 and 12 can beconfigured to interface with either 2-wire ICPtype transducers or 3-wire proximity probes.

Each dynamic channel can be independentlyconfigured with flexible signal processing

options. The Keyphasor channels interface toeither 3-wire proximity probes or other speed

sensors which are powered externally.The module provides enhanced capability for

monitoring rolling element bearing machineryand gearing through its 24 bit Analog/Digital .conversion and 40 kHz bandwidth design.The 60M100 System is not a substitute for hardwired safety systems, nor does it replace thestandard systems for the acquisition of

operational data of the wind turbine.60M100 OverviewThe 60M100 Condition Monitoring System isspecifically designed for continuouspermanent monitoring of wind turbinegenerator machine trains. It is designed tomonitor equipment that requires extremelyhigh reliability and availbility.

The 60M100 System is designed to monitor

essential characteristics and components of awind turbine, including:Tower swayMain bearingMain rotorGear boxes。All internal bearings2 All bear meshes。Debris monitoring

Generator bearingsGenerator groundingIf you need assistance configuring yourmonitoring solution, contact your local BentlyNevada sales professional or Bently Nevadasupport (bntechsupport.com).Digital CommunicationsThe 60M100 System includes digitalcommunication capabilities for connection toADAPT software using proprietary protocols viaEthernet connections. The 60M100 systemtransmits data via Ethernet TCP/IP. You canmonitor values and statusyour process and control and otherautomation systems.provides extensive communication capabilitiesof all monitored values and statuses forintegration with process control and otherautomation systems using Ethernet TCP/IPcommunications capabilities. It permitsEthernet communications with other 60M100systems and System_ Software. Supported

-100x100.jpg)

Reviews

There are no reviews yet.