Description

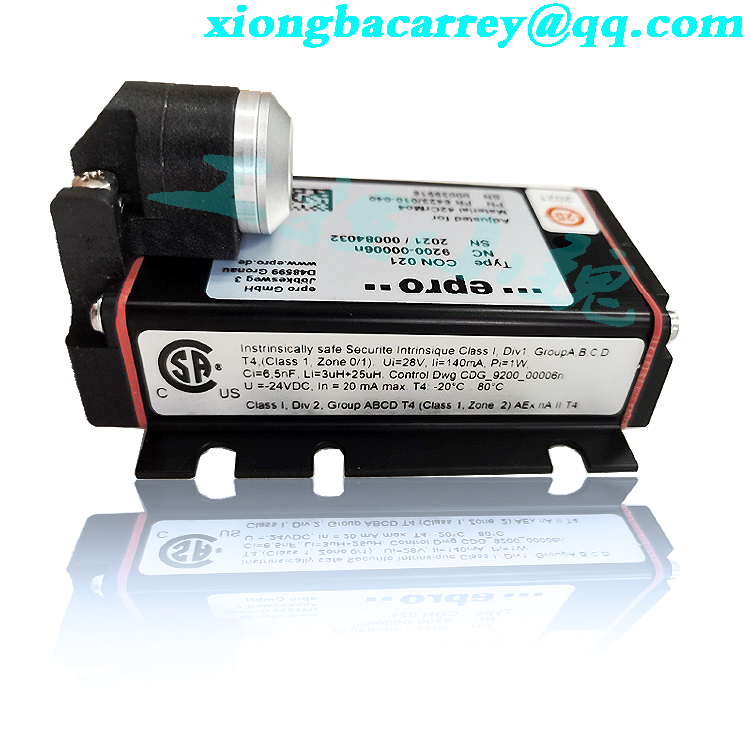

Eddy Current Displacement Transducer Specifications The PR 6423 is a non-contact eddy current transducer with a rugged construction and designed for extremely critical turbomachinery applications such as steam, gas, compressor and hydro turbomachinery, blowers and fans. The purpose of a displacement probe is to measure position or shaft movement without contacting the measured surface – the rotor. In the case of sleeve bearing machines, the shaft is separated from the bearing material by a thin film of oil. The oil acts as a dampener and therefore the vibration and position of the shaft are not transmitted through the bearing to the bearing case. The use of case vibration sensors is discouraged for monitoring sleeve bearing machines since the vibration produced by shaft motion or position is greatly attenuated through the bearing oil film. The ideal method of monitoring shaft position and motion is by mounting a non-contact eddy sensor through the bearing, or inside the bearing, measuring the shaft motion and position directly. The PR 6423 is commonly used to measure vibration of machine shafts, eccentricity, thrust (axial displacement), differential expansion, valve position, and air gaps. www.assetweb.com/mhm Q Non-contact measurement of static and dynamic shaft displacement – Axial and radial shaft displacement (position) – Shaft eccentricity – Shaft vibration (motion) Q Meets international standards, DIN 45670, ISO 10817-1 and API 670 Q Rated for explosive area, Eex ib IIC T6/T4 Q Other displacement sensor selections include PR 6422, PR 6423, PR 6424 and PR 6425 Q Select converter, such as CON 011/91, 021/91, 041/91, and cable for complete transducer system

EPRO MMS6823R 9100-00001-06 displacement monitor. Dual channel axis displacement monitor Dual channel axis displacement monitor project number.: MMS6823 for industrial process control systems

1. Function

The engine speed sensor, also known as the crankshaft position sensor (Figure a), is installed on the flywheel housing or at the front end of the crankshaft, and some old-fashioned engines

(For example, the Toyota 8A engine) is installed inside the power distributor, and its function is to measure the speed and angle of the crankshaft or power distributor shaft, and provide it to the ECU

Provide engine speed signals and crankshaft angle signals as the main control signals for fuel injection and ignition control, as shown in the following figure.

Installation position of speed sensor

The camshaft position sensor (Figure b) is installed at the front or rear end of the camshaft, and the old-fashioned engine is installed in the power distributor, its function is to

Provide the ECU with the crankshaft angle reference position (top dead center of the first cylinder compression) signal as the control unit to calculate the injection time and ignition time

Auxiliary signal between.

The function of the speed sensor is to:

1. The engine speed sensor, also known as the crankshaft position sensor, is one of the most important sensors in the electronic fuel injection engine control system. The function of the engine speed sensor is to detect the engine speed, which can determine the position of the crankshaft, detect the top dead center signal of the piston and the crankshaft angle signal, and transmit the detected signal to the ECU for controlling the ignition timing and fuel injection timing;

2. The structure and working principle of the engine speed sensor and camshaft position sensor are basically the same, and mutual cooperation is necessary to ensure the normal operation of the engine. Usually installed together, usually in the power distributor, mounted on the gearbox clutch housing, at the front or rear of the crankshaft, using a pulse signal type speed sensor to measure the engine speed. Some are installed on the front end of the crankshaft, the front end of the concave wheel shaft, or the flywheel, and the specific installation position depends on the type of engine speed sensor;

Symptoms of engine speed sensor damage include:

1. Engine instability during idle speed;

2. When the vehicle slows down and stops during starting or driving, there is an instant stop or stalling phenomenon;

3. Reduced engine acceleration performance;

4. The instrument speed display is uneven;

5. The engine malfunction indicator light is on.

The speed sensor is generally installed on the power distributor or engine and can detect the rotation angle of the crankshaft. However, if a malfunction occurs, the

operation of the ignition system will be disrupted and the engine will not be able to operate.

Most speed sensors are magnetic pulse type, so they can emit weak electrical signals. A multimeter or oscilloscope can be used for detection.

Speed sensors can be classified based on their physical quantities, working principles, and the properties of their output signals. Their role is to:

1. The engine speed sensor detects the engine speed, controls the ignition timing and fuel injection timing;

2. The engine speed sensor and camshaft position sensor cooperate with each other to ensure the normal operation of the engine;

3. Engine speed sensors are divided into three types based on the principle of generating signals: magnetic induction, photoelectric, and Hall type. Electromagnetic

induction speed sensors are divided into 2-wire or 3-wire types, but general Hall type speed sensors are 3-wire types, with 2 lines being the power line and AC signal line

respectively. The third line of the 3 lines is the AC signal shielding line, which is connected to the iron.

| EPRO NEW ARRIVAL LIST IN STOCK | ||

| PR6424/012-000 CON011 | A6110 | MMS6410 |

| PR6423/000-131-CN CON031 | A6312 | MMS6110 |

| PR6423/002-040 CON041 | A6410 | MMS6220 |

| CON021+PR6423/003-130 | A6210 | MMS6210 |

| CON021+PR6423/10R-030-CN | A6120 | MMS6250 |

| CON021+PR6423/013-000 | A6312/06 | MMS6312 |

| CON021+PR6423/10R-030-CN | PR9376/20 | MMS6210 |

| CON021+PR6423/10R-030-CN | CON021 | CON041 |

| CON041/SF+PR6423/015-111 | CON011 | CON031 |

Reviews

There are no reviews yet.