Description

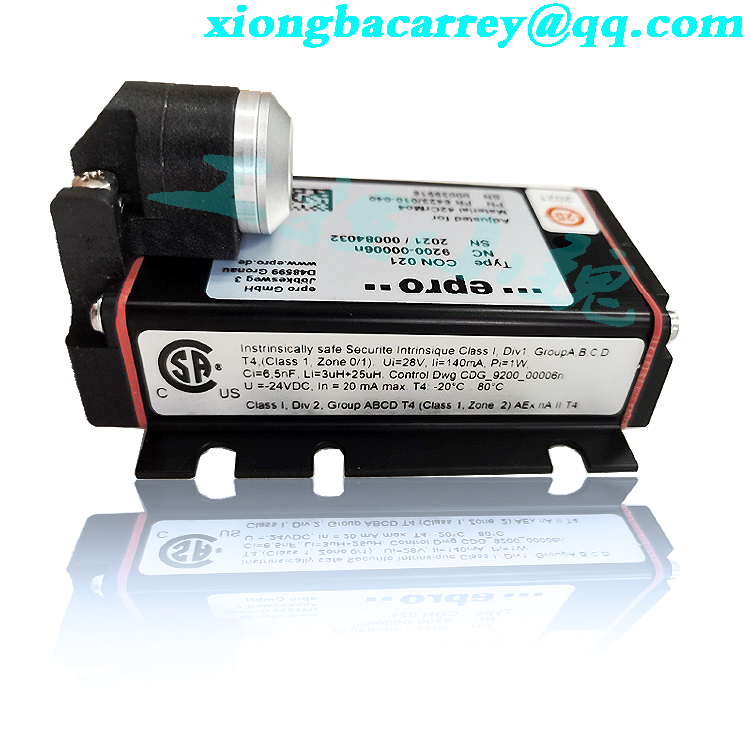

PR6426/010-000 is an eddy current sensor. Non contact sensors are designed specifically for critical turbomachinery applications such as steam, gas, and hydraulic turbines, compressors, pumps, and fans, to measure radial and axial shaft displacement: position, eccentricity, and motion.

The function and type of the CKP camshaft position (CMP) sensor

1. Function

The engine speed sensor, also known as the crankshaft position sensor (Figure a), is installed on the flywheel housing or at the front end of the crankshaft, and some old-fashioned engines

(For example, the Toyota 8A engine) is installed inside the power distributor, and its function is to measure the speed and angle of the crankshaft or power distributor shaft, and provide it to the ECU

Provide engine speed signals and crankshaft angle signals as the main control signals for fuel injection and ignition control, as shown in the following figure.

Installation position of speed sensor

The camshaft position sensor (Figure b) is installed at the front or rear end of the camshaft, and the old-fashioned engine is installed in the power distributor, its function is to

Provide the ECU with the crankshaft angle reference position (top dead center of the first cylinder compression) signal as the control unit to calculate the injection time and ignition time

Auxiliary signal between.

The function of the speed sensor is to:

1. The engine speed sensor, also known as the crankshaft position sensor, is one of the most important sensors in the electronic fuel injection engine control system. The function of the engine speed sensor is to detect the engine speed, which can determine the position of the crankshaft, detect the top dead center signal of the piston and the crankshaft angle signal, and transmit the detected signal to the ECU for controlling the ignition timing and fuel injection timing;

2. The structure and working principle of the engine speed sensor and camshaft position sensor are basically the same, and mutual cooperation is necessary to ensure the normal operation of the engine. Usually installed together, usually in the power distributor, mounted on the gearbox clutch housing, at the front or rear of the crankshaft, using a pulse signal type speed sensor to measure the engine speed. Some are installed on the front end of the crankshaft, the front end of the concave wheel shaft, or the flywheel, and the specific installation position depends on the type of engine speed sensor;

3. Engine speed sensors can be divided into three types based on the principle of signal generation: magnetic induction, photoelectric, and Hall type. Electromagnetic induction speed sensors are divided into 2-wire or 3-wire systems, while the common Hall type speed sensors are 3-wire systems. The two wires are the power line and the AC signal line, while the third wire of the three wires is the AC signal shielding wire, which is connected to the ground. Operating principle of speed sensor:

1. When measuring the speed of mechanical equipment using a speed sensor, the metal gears, racks, and other moving parts of the measured machinery will pass through the front end of the sensor, causing corresponding changes in the magnetic field. When the moving parts pass through the area where the magnetic field lines generated by the Hall element are relatively scattered, the magnetic field is relatively weak, while when passing through the area where the magnetic field lines generated are relatively few, the magnetic field is relatively strong;

2. The Hall speed sensor generates Hall potential when the magnetic field density changes and passes through the sensing element on the sensor. The Hall component of the Hall speed sensor generates Hall potential and converts it into an alternating electrical signal. Finally, the built-in circuit of the sensor adjusts and amplifies the signal to output a rectangular pulse signal;

3. The measurement method of Hall speed sensor must be in line with the changes in magnetic field. Therefore, when measuring equipment made of non ferromagnetic materials using Hall speed sensor, it is necessary to install a specialized magnetic material on the rotating object in advance to change the magnetic field around the sensor, so that the Hall speed sensor can accurately capture the motion state of the material.

Reviews

There are no reviews yet.