Description

369-HI-0-0-0-0-0 technical specifications Control power input range 110 to 250 VDC, 100 to 240 VAC, 50/60 Hz Ground current input frequency 20 to 100 Hz Operating range -40 ° F to+140 ° F Phase current input conversion true RMS, 1.04 milliseconds/sample software EnerVista 369 Storage range -40 ° F to+176 ° F Waveform capture length including 16 cycles of all current and voltage channels 3 buffers

Product Description

When you need to specify protection and monitoring for three-phase motors and mechanical systems, the 369 motor management relay series is the ideal choice. By providing FlexCurve ™ Custom overflow curve allows you to achieve maximum motor protection in a single relay. The 369-HI-0-0-0-0 model also has learning ability to identify and adapt to various motor parameters. This adaptability enables your system to operate in a manner suitable for specific industrial applications. Therefore, if managing versatility is something that your device can use, then this is the right series for you. We offer a series of 369 motor management relay systems at prices suitable for various equipment budgets.

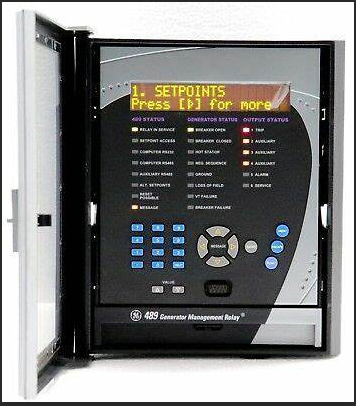

The height of 369-HI-0-0-0-0 is about 30 centimeters, the length is about 21 centimeters, and the width is about 11 centimeters. This device is installed in a DEMO metal suitcase and has anti-corrosion and flame retardant functions. The incoming weight of 369-HI-0-0-0-0 is 10 pounds, and the outgoing weight is approximately 8 pounds. Strong magnetic fields and high current conductors can damage the relay when approaching, so users should pay attention to installing the relay away from such hazards. The front of the relay is roughly divided into four parts, including a LCD display screen,

multiple LED indicator lights, a keyboard for manual input of set values and navigation, and an RS232 port 369.369 for connecting to a computer running the leading software program EnerVista in the general electrical industry. The motor management relay is a digital relay that provides protection and monitoring of three-phase motors and their related mechanical systems. The unique feature of the 369 Reloy is the ability to “learn” individual motor porosity meters and adopt them for each application itself. Values such as motor inrush current, current, and acceleration time can be used to improve the protection coordination ability of the 369 relay. The 369 relay customizes the overload curve using FlexCurveTM, or one of the Feen Stondard curves. The 369 relay has one RS232 front panel port and three RS485 rear panel ports.

The Modbus RTU protocol is strict for all ports. The set point can be entered through the front keyboard, or the EnerVista 369 installation software and computer Stotus can be used. The actual values and troubleshooting information can also be displayed through the front panel display or through communication. As an option, the 369 Reloy can independently monitor up to 12 RTDS. These can come from stators, bearings, engines, or driven equipment. The type of resistance temperature detector used can be soft wear. The remote resistance temperature detector module (optional) can be provided as an accessory and can be connected to a 369 relay connected via fiber optic or RS485. The optional metering packaging provides VT inputs for voltage and power components.

.jpg)

It also provides metering for V, kW, kVA, PF, Hz, and MWhrs. The other three user configurable analog outputs are included in this option along with an onalog output as part of the basic unit. Reverse rotation detection (BI option enables the 369 relay to detect flow reverse pump motor, enabling the motor to restart in a timely and safe manner.

Motor management relay, 12 RTD inputs, metering package, enhanced diagnosis, 50-300 V DC, 60-265 V AC 369 designed specifically for medium voltage motors, providing simple setting configuration through the use of motor settings automatic configurator, advanced graphical diagnosis using motor health reports, comprehensive communication using multiple communication options, and full tracking of all setting changes using safety settings changes historical reports, Providing unparalleled motor protection for medium-sized AC motors. Also known as: 369-HI-RM-0-0-0-E

More recommendations:

369-HI-R-M-F-E-H-E GE

-100x100.jpg)

-300x300.jpg)

Reviews

There are no reviews yet.