Description

Many products have not been listed yet. For more products, please contact us

If the product model is inconsistent with the displayed image, the model shall prevail. Please contact us for specific product images, and we will arrange for photos to be taken and confirmed in the warehouse

We have 16 shared warehouses worldwide, so sometimes it may take several hours to accurately return to you. We apologize for any inconvenience caused. Of course, we will respond to your concerns as soon as possible.

HIEE300744R1 Other names:

Input/output module HIEE300744R1

HIEE300744R1PLC module

PLC controller HIEE300744R1

HIEE300744R1interface board

HIEE300744R1 programmable control module. PLC is an electronic system for digital operations, designed specifically for use in industrial environments. It uses programmable memory to store instructions for performing logical operations, sequential control, timing, counting, and arithmetic operations within it, and controls various types of mechanical equipment or production processes through digital or analog inputs and outputs.

HIEE300744R1 PLC module is a colloquial term used in PLC systems to refer to various parts based on their functional usage. It mainly includes the following types:

Power module: The unit part that provides working power for the PLC system.

CPU module: The core component of a PLC system, mainly responsible for processing input signals, executing program instructions, controlling output signals, and providing monitoring and diagnostic functions. CPU modules typically include parts such as the central processing unit, memory, and communication interfaces.

I/O module: Input and output modules, usually divided into analog signals and digital signals. The input module is used to collect external signals, such as sensor signals, button signals, switch signals, etc; The output module is used to control external devices such as motors, valves, etc.

Communication module: used to achieve data communication between PLC system and other devices, usually including Ethernet module, serial communication module, CAN bus module, etc.

In addition, the PLC module also has the following functions:

Position control: Most PLC manufacturers offer single axis or multi axis position control modules for dragging stepper or servo motors.

Process control: closed-loop control of analog variables with continuous changes in temperature, pressure, flow rate, etc..jpg)

Data processing: It has functions such as mathematical operations, data transmission, conversion, sorting, table lookup, and bit operations, and can also complete data collection, analysis, and processing.

High precision control: The HIEE300744R1 motor controller adopts advanced control algorithms and high-speed processors, which can achieve precise control of the motor, including parameters such as speed, position, and torque.

Wide speed regulation range: This motor controller usually has a wide speed regulation range, which can meet the speed requirements of different applications, and can achieve smooth and accurate control from low speed to high speed.

Fast dynamic response: The motor controller has the ability to quickly respond to instructions from the superior control system, achieving fast start, stop, and speed adjustment of the motor.

Multiple control modes: This motor controller supports multiple control modes, such as speed control, position control, torque control, etc., to meet the needs of different application scenarios.

Complete protection function: The HIEE300744R1 motor controller has comprehensive protection functions, such as overcurrent protection, overvoltage protection, undervoltage protection, overheating protection, etc., to ensure that the motor can safely stop in abnormal situations and avoid equipment damage.

The workflow of the PLC module is roughly as follows:

When the input signal changes, the PLC will collect these signals and convert them into digital signals.

Use specific programming languages (such as ladder diagram programming language or structured text language) to program the PLC and implement the required control logic.

According to programming logic, the PLC controls the output equipment for corresponding action control.

PLC will continuously check input signals, update output signals, and adjust and execute control logic as needed.

PLC can communicate with upper computer or other PLCs and exchange data to achieve more complex control functions.

All products on this website are special products, and market prices have been fluctuating,

The specific customer service quotation shall prevail, as the product is a new product and the price is not genuine,

Please confirm the model, product, price, and other detailed information with customer service before placing an order. The website has been used,

The new one is for sale, please contact customer service to communicate.

Warehouse discount product recommendation:

IS420PUAAH1A

UAA326A04

HIEE300024R4

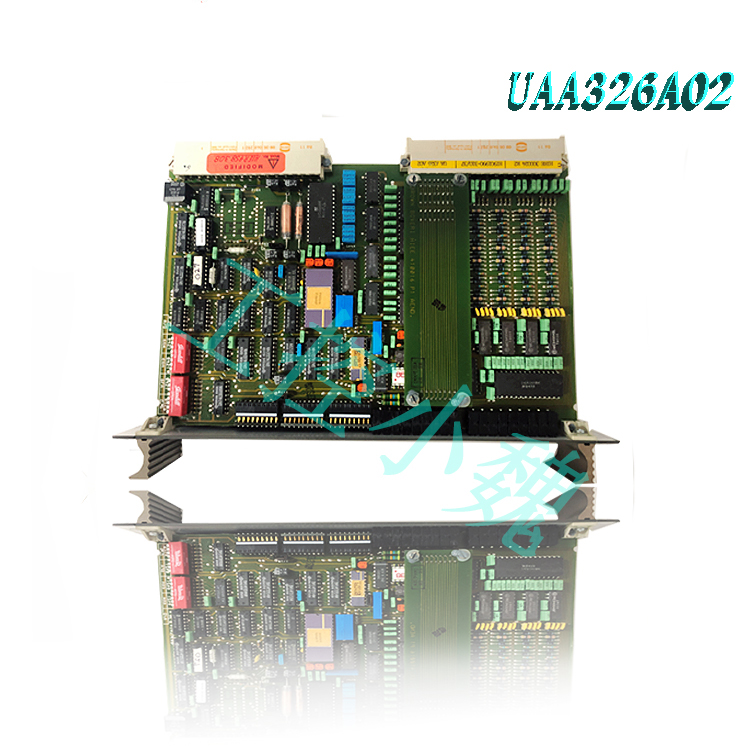

UAA326A02

UAA326A02

UAA326A04

HIEE300024R4 UAA326A04

UAA326A02 HIEE300024R2

UAA326A02

UAA326A02 HIEE300024R2

More……

-100x100.jpg)

-1-300x300.jpg)

-300x300.jpg)

Reviews

There are no reviews yet.