Description

IS200VCMIH2BCC Technical Specifications

Manufacturer General Electric

Product Description

IS200VCMIH2BCC is a GE Mark VI printed circuit board. This is a Mark VI component. Mark VI is a steam and gas turbine management system released by General Electric as part of the “Speedtronic” series. Since the 1960s, the Speedtronic series has been used in various iterations of turbine management. Mark VI meets or exceeds many safety and quality assurance standards, including ISO-9000-3 Quality Management and Quality Assurance Standards, Part 3: Guidelines for Developing, Supplying, and Maintaining Software Using ISO-9001.

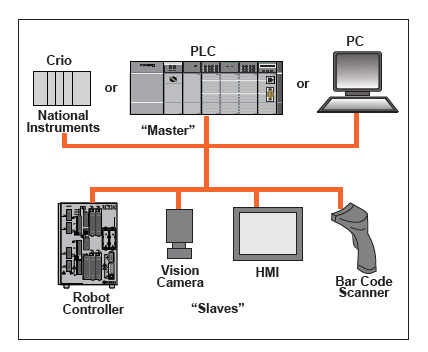

IS200VCMIH2BCC is designed to be installed in slot 1 of the central control module. It serves as an internal communication control card, allowing I/O cards within the rack or other control or protection modules to communicate with each other.

The IS200VCMIH2BCC has a narrow front panel with many components installed on its surface. This includes a 9-pin serial port, three DIN connectors (IONet1, IONet2, and IONet3), a reset switch, and twenty LED indicators. LEDs are placed on the circuit board in three, eight, six, and three groups. All components have been marked.

.jpg)

The IS200VCMIH2BCC has multiple connector components, including two backplanes, two vertical pin connectors, and multiple conductive trace connectors. There are three transformers and over fifty integrated circuits on the circuit board, including FPGA (Field Programmable Gate Array). There are over 25 inductive magnetic beads on the circuit board, distributed in several rows on the surface of the circuit board. This board has capacitors, resistors, and diodes. The board uses two surfaces (front and back) to place components.

.jpg)

IS200VCMIH2BCC

IS200VCMIH2BCC is a Mark VI VME communication board. The VCMI board in the control and interface module communicates internally with the I/O board in its rack, and communicates with other IS200VCMIH2BCC cards through IONet. This is mainly used for the GE Speedtronic Mark VI series. In addition, Mark VI is a flexible platform suitable for multiple applications. It also provides high-speed networked I/O for single redundant, dual redundant, and triple redundant systems.

IS200VCMIH2BCC is a multi-layer PCB filled with SMD components and connectors.

reliability

The IS200VCMIH2BCC board is very reliable and not easily damaged. However, improper handling and storage can affect the functionality of the card. Therefore, we recommend storing the card in an electrostatic sensitive storage box under recommended conditions.

Repairing

If you encounter any issues while using IS200VCMIH2BCC, we can quickly test, diagnose, and fix it. IS200VCMIH2BCC can use accelerated repair options. These cards are repaired using appropriate tools and experts in a controlled environment. All the parts required to repair this board are in our inventory. We also ensure that the replacement parts are industrial grade and meet or exceed OEM standards. FVT has tested all repairs and provided warranty.

Refurbishment

Properly refurbishing the IS200VCMIH2BCC circuit board can extend its service life.

The refurbishment process includes:,

Replace all aging and common faulty components.

Apply TIL modifications (if any).

Reflow solder to eliminate dry solder.

Thorough industrial standard cleaning of the card.

Apply protective layer, etc.

Functional verification test

We perform the Functional verification test of IS200VCMIH2BCC in the actual OEM system settings. Because we use OEM systems, we can guarantee 100% reliability. Like any other card, all inputs and outputs will be individually verified for functionality. So each channel is verified separately. According to different circuit boards, we conduct load testing to ensure proper stability of the circuit board.

Circuit board processing.

IS200VCMIH2BCC is an electrostatic sensitive board.

We recommend minimizing manual contact with PCBs, especially in conductive areas. If you need to hold them directly, please hold their edges. Always wear anti-static gloves. These devices require appropriate ESD safety precautions to be taken to handle them.

These products are open-box genuine OEM products from independent third parties.

These equipment are subject to our quality inspection plan, which includes comprehensive Functional verification tests and verifies whether the results meet the manufacturer’s specifications.

The basic principle of PLC selection is to choose the most reliable, convenient for maintenance, and

On the premise of meeting the functional requirements, the model with the best cost-effectiveness.

Generally speaking, when the process is relatively fixed and the environmental conditions are good,

It is recommended to use a single-chip structure PLC; In other cases, it is best to use a modular PLC structure.

Programmable controller is a digital operated electronic system designed specifically for use in industrial environments

And design. It uses programmable memory to store logical operations, timing control, timing

The counting and arithmetic operations in its internal control are achieved by controlling various types of machinery or production

Digital analog input output process. Programmable controllers and related equipment should be designed

Easy to integrate with industrial control systems and expand.

We not only fix the problem, but also replace aging and common faulty components, even if they function normally during repair, which increases the reliability of the circuit board.

Can provide daily turnover maintenance services upon request

All of our repairs come with a 2-year warranty.

Model recommendation: EPRO PR6423/00R-010 CON021

-100x100.jpg)

-100x100.jpg)

-300x300.jpg)

-300x300.jpg)

Reviews

There are no reviews yet.