Description

Many products have not been listed yet. For more products, please contact us

If the product model is inconsistent with the displayed image, the model shall prevail. Please contact us for specific product images, and we will arrange for photos to be taken and confirmed in the warehouse

We have 16 shared warehouses worldwide, so sometimes it may take several hours to accurately return to you. We apologize for any inconvenience caused. Of course, we will respond to your concerns as soon as possible.

International Approvals The Tricon controller has been certified as complying with multiple internationally recognized standards by the following internationally recognized certification agencies, these certifications have qualified the Tricon for use around the world in safety critical applications. Test reports from the various certification agencies are available upon request. TÜV Rheinland — TÜV has certified that the Tricon v9 and v10 controllers are in full compliance with the internationally recognized standards listed below, and thus are qualified for use in the following applications and jurisdictions. • Emergency safety shut-down or other critical control applications requiring SIL 1-3 certification per the functional safety requirements of IEC 61508 9 (only Tricon v9.6 or later) • Emergency safety shut-down or other critical control applications requiring AK 1-AK6 certification per the functional safety requirements of DIN V 19250 and DIN V VDE 0801 (only Tricon v9.x) • Fire and gas detection applications requiring certification per the requirements of EN 54 • Fire and gas detection applications requiring certification per the requirements of NFPA 72 (only Tricon v9.6 or later) • Burner management applications requiring certification per the requirements of DIN VDE 0116 • Burner management applications requiring certification per the requirements of NFPA 8501 or NFPA 8502 (only Tricon v9.6 or later) • All applications in the European Union or other jurisdictions requiring compliance with the EMC Directive No. 89/336/EEC and Low Voltage Equipment Directive No. 72/23/EEC • All applications in the European Union or other jurisdictions requiring compliance with the ATEX Directive No. 94/9/EC for Zone 2, Group IIB hazardous locations • Environmental, health, and safety applications in semiconductor manufacturing facilities per the requirements of SEMI S2 For hazardous location applications, see the Tricon Planning and Installation Guide for application-specific installation instructions. Canadian Standards Association (CSA) — CSA has certified that the Tricon v10 controller is in full compliance with the internationally recognized electrical safety standards and is qualified for general use in North American and other jurisdictions requiring compliance with these standards. Factory Mutual Research (FM) — Factory Mutual has certified that the Tricon v10 controller is in full compliance with the international recognized standards and is qualified for use in Class I, Division 2 Temperature T4, Groups A, B, C, and D hazardous indoor (or outdoor in a NEMA 4 cabinet) locations. For hazardous location applications, see the Tricon Planning and Installation Guide for application-specific installation instructions. European Union CE Mark — Based upon the independent TÜV evaluation and test results, Triconex has certified the Tricon controller is suitable to use in the European Union and all other jurisdictions requiring compliance with the European Union EMC Directive No. 89/336/EEC and Low Voltage Equipment Directive No. 72/23/EEC, see Certificate of Compliance for details. For hazardous location applications, see the Tricon Planning and Installation Guide for application-specific installation instructions.

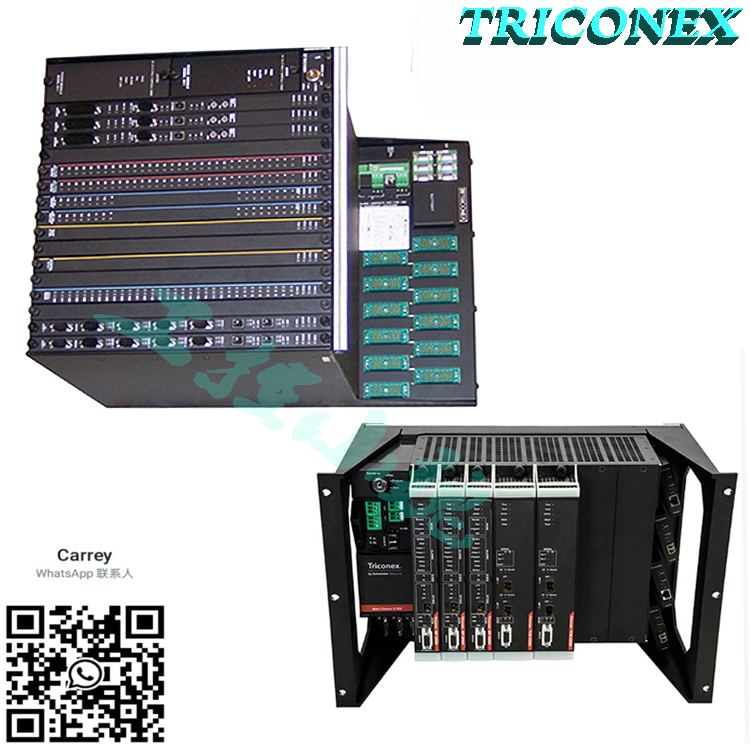

Chassis Options A Tricon system is made up of one or more chassis assemblies which contain I/O and communication modules. The first chassis of a system is called the Main Chassis (Model 8110). To enlarge a system, Expansion Chassis (Model 8111 or 8121) and/or RXM Chassis (Model 8112) can be added. (See “System Configuration” on page 11 for details.) I/O Expansion Bus Each chassis has six RS-485 I/O expansion bus ports at the top left corner of the backplane. There are two sets of ports for channels A, B, and C, providing for two triplicated serial communications paths between chassis. One set of cables is required for each Expansion Chassis and for the RXM Chassis which houses the primary RXM Module set. The standard length of a cable set (Model 9000) is 6 feet— longer cables are available if needed. The triplicated I/O bus transfers data between the I/O modules and the Main Processors at 375 kilobits per second. The communication bus runs between the Main Processors and the communication mohttps://www.weikunfadacai1.com/

Advanced Communication Module (ACM) The Model 4609 Advanced Communication Module (ACM) acts as an interface between a Tricon controller and a Foxboro Intelligent Automation (I/A) Series system, appearing to the Foxboro system as a safety node on the I/A Series Nodebus. The ACM communicates process information at full network data rates for use anywhere on the I/A Series system, transmitting all Tricon aliased data (including system variables and system aliases) and diagnostic information to operator workstations in display formats that are familiar to Foxboro operators. The ACM makes the following functions available to the I/A Series: • Handles critical I/O points and passes results to the I/A Series using the Object Management Database (OMDB) • Processes Tricon alarms and propagates them to user-defined I/A Series destinations (consoles, printers, etc.) • Propagates Tricon alarms as I/A Series system messages • Reads/writes aliased data to satisfy I/A Series requests • Time synchronization from the I/A Series environment • Reads Tricon diagnostics for display by the I/A Series workstation • Write protection to lock out changes to the Tricon controller from all I/A Series sources • Hot-spare capability for uninterrupted communication with the I/A Series Nodebus The ACM also supports the following Triconex protocols and applications on external host PCs connected to a separate BNC port (labeled NET 2): • Tristation protocol for the TriStation 1131 software • TSAA protocol for Triconex applications • TSAA/TCP (UDP/IP) for userwritten applications on external hostshttps://www.weikunfadacai1.com/

Remote Extender Module (RXM) RXMs and chassis allow I/O modules to be located several kilometers from the Main Chassis. RXM sets, consisting of three identical modules, serve as repeaters and extenders of the Tricon I/O bus and provide ground loop isolation. A primary RXM set supports three remote locations by connecting to three remote RXM sets housed in a remote chassis. See “System Configuration” on page 11 regarding configurations that use RXMs. RXM sets are available for fiber-optic cables with a communication rate of 375 kilobits per second. These sets provide maximum immunity against electro-static and electro-magnetic interference, and support configurations with optical modems and fiberoptic point-to-point cabling. Remote sites can be located as far as 7.5 miles (12 kilometers) from the primary site. The figure at right shows uni-directional cabling for three channels of a remote location. For each channel, one cable carries data transmitted from the primary RXM to the remote RXM, and the other cable carries data received by the primary RXM from the remote RXM. A pair of modules must be wired for each of the three channels, amounting to a total of six cables for each remote location.

Recommended warehouse spare parts:

WEIDMULLER 410102-3 SKHD-32S TERMINAL MODULE

WHESSOE 00030-7815-3 COMMUNICATION MODULE

YOSHIDA ELECTRIC PS7D-50V4 MODULE

YOSHIDA ELECTRIC PS7D-20V4 MODULE

ZOLLER ELEKTROTECHNIK AHD-418 BOW THRUSTER CONTROL MODULE

VERO ELECTRONICS TRIVOLT-PK110-116-032362K POWER SUPPLY MODULE

VERO ELECTRONICS MONOVOLT-PK60-116-033433H POWER SUPPLY MODULE

THORN SECURITY ASSY.125-485-850-ALXM ALARM LOOP EXPANSION MODULE

Reviews

There are no reviews yet.