Description

Many products are not yet on the shelves, please contact us for more products

If the product model is inconsistent with the display picture, the model shall prevail. Please contact us for specific product pictures, and we will arrange to take photos in the warehouse for confirmation

We have 16 shared warehouses around the world, so sometimes it may take several hours to return to you accurately, please understand. Of course, we will respond to your concerns as soon as possible.

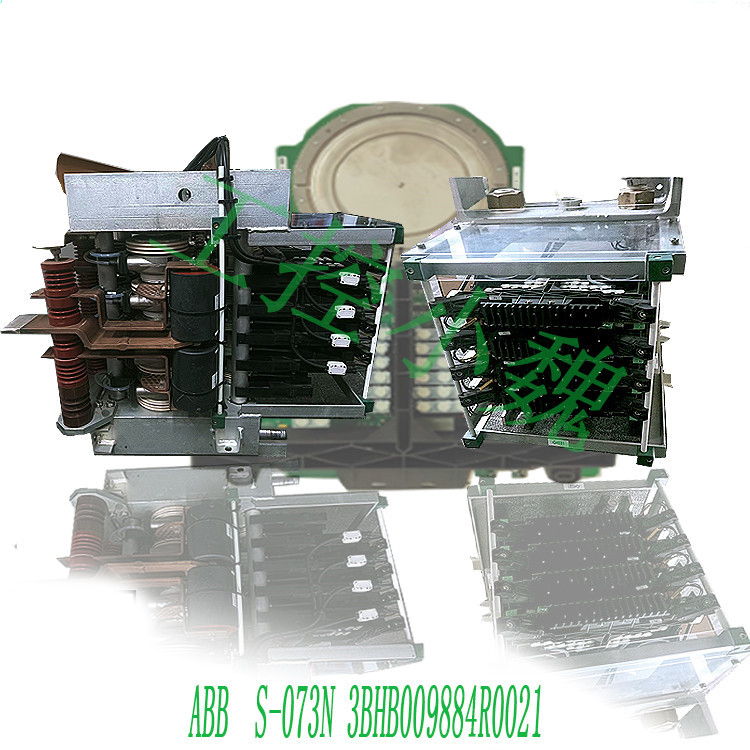

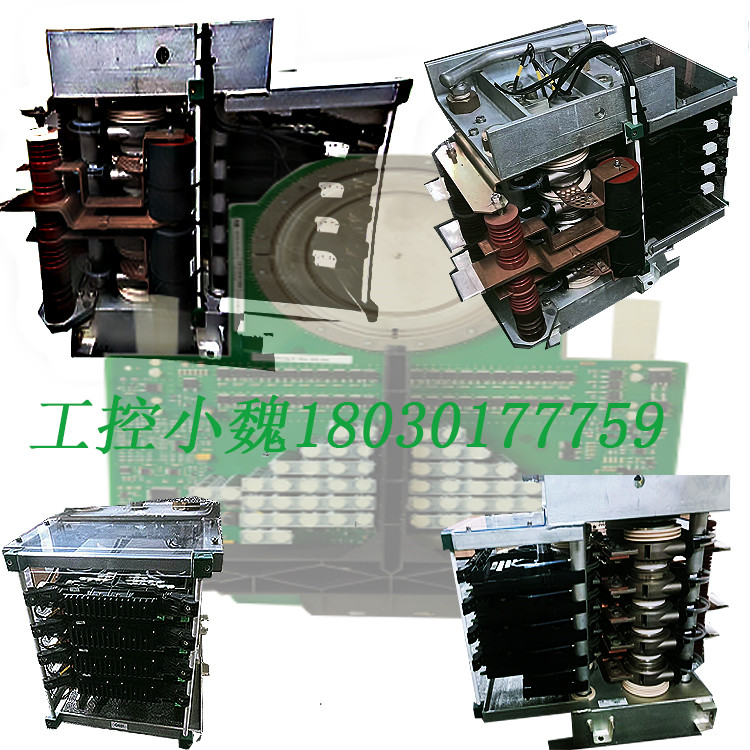

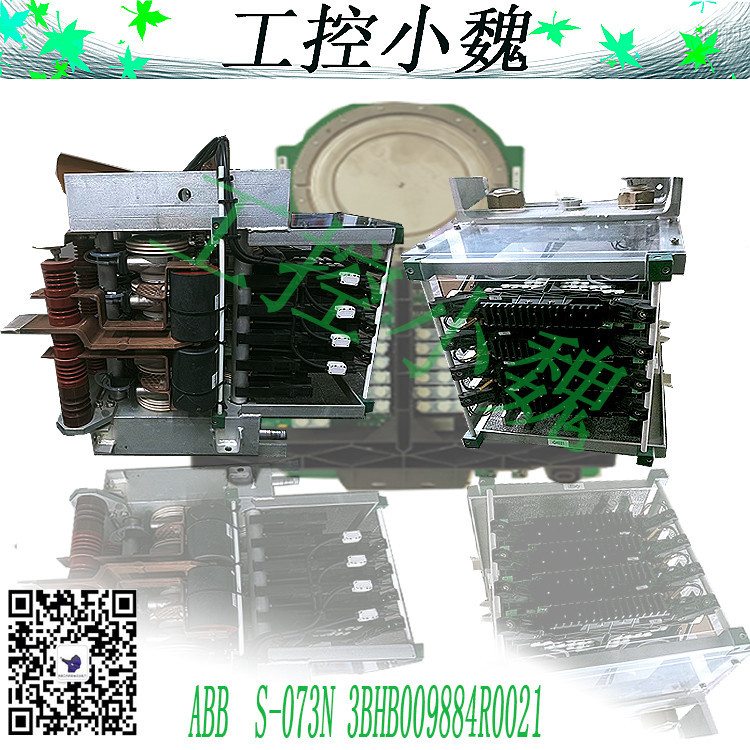

Other names of S-073N 3BHB009884R0021:

IGCT module S-073N 3BHB009884R0021

S-073N 3BHB009884R0021 high-voltage inverter module

Editable controller module S-073N 3BHB009884R0021

S-073N 3BHB009884R0021 is a phase module for high-voltage TV sets, belonging to the ABB ACS2000 series, mainly used to control motor speed and operation. It can be used in combination with other IGCT modules to build a complete high-voltage sunshade system. The module is able to distribute the phase of the input signal to obtain output signals of different phases. In the field of electronic technology, phase distribution modules are widely used in various signal processing systems, such as communication systems, radar systems, measurement systems, etc., to ensure that signals can be correctly parsed and processed during transmission.

The main features include:

It is a key component in the high-voltage inverter system.

It is used to control the speed and operation of the motor to achieve energy saving and improve productivity.

It is mainly evaluated in the power and industrial fields.

The mechanical structure of the module includes:

Enclosed box

Internal structure (IEGT unit, layered unit, upper and lower water distributor, insulation interval)

Overall structural design

Application field

Communication field: In wireless communication, the S-073N 3BHB009884R0021 phase distribution module can effectively improve the transmission efficiency and quality of the signal, thereby improving the overall performance of the communication system.

Radar technology: In the radar system, the S-073N 3BHB009884R0021 phase distribution module can achieve precise control of the radar signal, thereby enhancing the detection accuracy and anti-interference ability of the radar.

Electronic countermeasures: In the field of electronic countermeasures, the S-073N 3BHB009884R0021 phase distribution module can be used to interfere with and deceive enemy signals to improve the survivability of our system.

Development trend

Technological progress: With the continuous development of microwave technology, the performance of the phase distribution module will be further improved to achieve more precise phase control.

Application expansion: With the continuous deepening of the application of phase distribution modules in various fields, there will be more fields that need to apply phase distribution module technology in the future.

Intelligence: With the development of artificial intelligence technology, the phase distribution module is expected to be intelligent in the future, further improving the automation level and performance of the system.

Phase detection principle

Phase detection is not a single signal detection, but the detection of the parameter difference between two signals of the same frequency. Zero-crossing detection is a widely used method in phase detection. It converts the input signal into the corresponding zero-crossing high and low levels by testing the shaping of the signal. By comparing the relationship between the high and low levels of the reference signal and the high and low levels of the signal to be measured, the corresponding phase parameters can be obtained.

Phase detection module

The phase detection module mainly detects the amplitude phase value of the microwave signal, and compares the changed phase with the unchanged phase, so as to facilitate data analysis. In some systems, the phase detection module may include components such as logarithmic amplifiers, phase detectors, and output amplifiers to achieve high-precision phase measurement.

In summary, as an important component in electronic technology, the phase module plays a key role in many fields. With the continuous advancement of technology and the expansion of application areas, the performance and intelligence level of the phase module will be further improved.

Introduction to ABB ACS2000 series

Rely on: Technologically advanced medium-voltage drives suitable for a variety of applications The medium-voltage ACS2000 drive is an industrial all-rounder that perfectly adapts to a variety of standard applications in all industries. A variety of options and drive configurations allow you to choose a perfectly matched product to improve the efficiency of processes and systems. Unlimited versatility enables the ACS2000 to perfectly adapt to different conditions and environments around the world, including hazardous areas. The simple design of the drive and the powerful control platform ensure reliable operation everywhere every day.

Highlights:

High reliability due to mature design and low number of parts

High compatibility with standard motors due to multi-level topology

Fuseless design

Constant network power factor over the entire speed range

Direct torque control (DTC)

Flexible input (DFE, 24 pulses, AFE, DTL with integrated transformer or external transformer)

Simple integration: 3 cables input – 3 cables output

Arc-resistant design

IEC and NEMA specific design

Power range 250 kW to 3.68 MW

All products on this website are special products, and market prices have been fluctuating.

Specifically, please refer to the customer service quotation, because the product is a new product, the price is not real,

Please confirm the model and product, price and other details with the customer service before placing an order, the website has been used,

New ones are on sale, please contact customer service for communication.

-300x300.jpg)

-300x300.jpg)

admin –

S-073N 3BHB009884R0021 is a phase module for high-voltage TV sets, belonging to the ABB ACS2000 series, mainly used to control motor speed and operation. It can be used in combination with other IGCT modules to build a complete high-voltage sunshade system. The module is able to distribute the phase of the input signal to obtain output signals of different phases. In the field of electronic technology, phase distribution modules are widely used in various signal processing systems, such as communication systems, radar systems, measurement systems, etc., to ensure that signals can be correctly parsed and processed during transmission.

admin –

Development trend

Technological progress: With the continuous development of microwave technology, the performance of the phase distribution module will be further improved to achieve more precise phase control.

Application expansion: With the continuous deepening of the application of phase distribution modules in various fields, there will be more fields that need to apply phase distribution module technology in the future.

Intelligence: With the development of artificial intelligence technology, the phase distribution module is expected to be intelligent in the future, further improving the automation level and performance of the system.

Phase detection principle

Phase detection is not a single signal detection, but the detection of the parameter difference between two signals of the same frequency. Zero-crossing detection is a widely used method in phase detection. It converts the input signal into the corresponding zero-crossing high and low levels by testing the shaping of the signal. By comparing the relationship between the high and low levels of the reference signal and the high and low levels of the signal to be measured, the corresponding phase parameters can be obtained.

admin –

The phase controller module adopts a unique fault-tolerant design to improve the reliability and stability of the system and supports redundant configuration to ensure that when the main controller fails, the backup controller can quickly take over the control task and monitor the operating status of the equipment in real time, diagnose potential faults, and provide fault alarm information for timely maintenance and replacement.

admin –

ACS6000 Medium Voltage AC Drive System Phase Controller Module S-073N 3BHB009884R0021

admin –

S-073N | ABB | phase controller module | 3BHB009884R0021 | 35SHY3545L0014

The phase controller module adopts a unique fault-tolerant design to improve the reliability and stability of the system and supports redundant configuration to ensure that when the main controller fails, the backup controller can quickly take over the control task and monitor the operating status of the equipment in real time, diagnose potential faults, and provide fault alarm information for timely maintenance and replacement.

admin –

The S-073N phase module (model: 3BHB009884R0021) of the ABB ACS 6000 system is a core component designed for medium-voltage AC drives. It adopts modular multilevel converter (MMC) technology, has high-precision phase control, efficient energy conversion and excellent reliability, and is widely used in high-power drive scenarios in metallurgy, mining, chemical industry, power and other industries.

Core parameters

Power range: 3-36MW, voltage level up to 3.3kV.

Phase control accuracy: real-time monitoring and adjustment of voltage/current phase to ensure efficient operation of the motor.

Semiconductor technology: IGCT (integrated gate commutated thyristor) is adopted, with low conduction loss, high blocking voltage (>4500V) and fast switching capability (μs level).

Modular design: supports flexible configuration, compatible with common DC bus, and realizes multi-motor coordinated operation and energy regeneration.

Key functions

Phase synchronization: In multi-motor systems (such as rolling mills and hoists), ensure that the phases of each motor are consistent to avoid vibration and efficiency loss.

Dynamic response: Quickly adjust the phase to adapt to sudden load changes (such as changes in crusher materials) and maintain stable torque output.

Energy-saving optimization: Reduce energy consumption and improve overall system efficiency (>98%) through precise phase control.

Fault protection: Integrated overvoltage, overcurrent and short-circuit protection, support fast restart (fuse-free design).

Application scenarios

1. Metallurgical industry

Rolling mill drive: In cold rolling/hot rolling production lines, S-073N ensures multi-motor phase synchronization, reduces rolling force fluctuations, and improves steel surface quality.

Case: In the Henan Zhongfu high-precision aluminum double-stand rolling mill project, the module successfully solved the tripping problem caused by IGCT damage and ensured continuous production.

2. Mining equipment

Crushers and hoists: To cope with harsh working conditions (dust, vibration), dynamic phase adjustment is used to maintain stable operation of the motor.

Case: In a coal mine hoist system, the module effectively handles sudden load changes and avoids high-voltage tripping.

3. Chemical and Electric Power

Pumps and Compressors: Optimize phase control, reduce energy consumption and equipment vibration, and extend service life.

Case: When a chemical pump transports different media, the module adapts to load changes to ensure stable operation.

Troubleshooting and Maintenance

1. Common Problems

IGCT damage: Performance degradation due to grid fluctuations or improper storage environment (such as long-term storage in a bonded area).

Phase synchronization failure: Phase difference in a multi-motor system causes efficiency reduction or tripping.

High-voltage tripping: Short circuit caused by loose busbar connection or insulation failure.

Troubleshooting steps

Preliminary inspection:

Verify grid voltage stability (within ±10% fluctuation range).

Check the tightness of wiring and busbar screws, and clean the insulation terminals.

Component test:

Measure IGCT on/off characteristics, diode and capacitance values (normal range: 4μF±10%).

Update the firmware or replace the faulty module (such as INT board, CVMI board).

In-depth diagnosis:

Check the connection between the transformer and the high-voltage cabinet, and check the discharge point (such as the contact between the water pipe and the copper busbar).

Use a datalogger to analyze the fault log.

3. Safety precautions

Before operation, ensure that the equipment is fully discharged and grounded, and maintenance is performed by professionals.

Avoid plugging and unplugging the module with power on to prevent IGCT from being damaged by static electricity.

Conclusion

The S-073N phase module is the core component of the ABB ACS 6000 system. Its high-precision phase control, modular design and IGCT technology make it excellent in the field of industrial transmission. Users need to strictly follow the installation, maintenance and troubleshooting procedures to ensure stable operation of the system.

admin –

ABB S-073N (model: 3BHB009884R0021) is the core phase control module of ACS6000 medium voltage AC drive system, designed for high voltage and high power industrial applications. The module ensures efficient and stable operation of the motor by accurately adjusting the voltage and current phase, and is widely used in power, metallurgy, petrochemical, mining and other industries.

Technical specifications and functions

1. Core parameters

Model and series: S-073N, belongs to ABB ACS6000 medium voltage AC drive system.

Input voltage range: DC 200-750V (adapted to high voltage environment).

Output power: 750W, current range 0-3A.

Control mode: supports position, speed, torque control, and has DCS-Link communication function (point-to-point high-speed data exchange).

Power semiconductor: uses IGCT (integrated gate commutated thyristor), supports high voltage (up to 3.3kV), large current, low conduction loss, and fast switching capability.

Circuit design: three-level topology, improve energy efficiency, simplify circuit complexity.

Key functions

Phase precision control:

Real-time monitoring of input voltage/current phase, adjusting output phase through advanced algorithms to ensure the best power supply phase for the motor.

In multi-motor synchronization scenarios (such as rolling mill drive), ensure the phase consistency of each motor to avoid vibration, noise and efficiency loss.

Dynamic response:

Based on direct torque control (DTC) technology, quickly adapt to load mutations (such as crusher material changes) and maintain stable torque output.

In wind power, chemical pumps and other scenarios, adapt to load characteristic changes and optimize operating efficiency.

Protection and reliability:

Built-in overvoltage, overcurrent, and short-circuit protection, support fast demagnetization (protect the generator in case of fault).

Modular design, support hot plugging, shorten maintenance downtime.

Industrial-grade design, adapt to harsh environments (high temperature, high humidity, vibration).

Application scenarios

1. Power industry

High-voltage motor drive: boiler fan, water pump, generator excitation control.

Renewable energy: power conversion and grid adaptation of wind/solar power generation system.

Substation: voltage regulation, reactive power compensation, improve grid stability.

2. Metallurgy and mining

Rolling mill control: multi-motor coordinated drive to ensure stable rolling force and improve steel surface quality.

Mining equipment: dynamic phase adjustment when the load of crusher and hoist changes suddenly to prevent overload damage.

3. Oil and gas

Compressor/pump control: efficient drive of natural gas pipeline and refinery equipment to adapt to medium changes.

Drilling platform: stable power supply of high-voltage motor to ensure continuous operation under complex working conditions.

4. Chemical and pharmaceutical

Mixer/centrifuge: precise speed regulation, reduced vibration, and extended equipment life.

Pump control: adaptive load when transporting chemical media to maintain stable flow and pressure.

5. Other fields

Cement building materials: energy-saving control of kiln blowers and crushers.

Rail transportation: subway/train electric drive, traction power supply system energy optimization.

Building automation: energy efficiency improvement of central air conditioning and elevator systems.

Troubleshooting and maintenance suggestions

1. Common problems and solutions

Possible causes of fault phenomena Solution steps

Module does not respond Power failure, firmware error or communication interruption 1. Check the stability of the input power supply (DC 200-750V) and confirm that there is no phase loss or fluctuation.

2. Update the firmware to the latest version and reset the parameters to the default values.

3. Check the DCS-Link communication line connection.

Phase control abnormality Sensor failure or parameter configuration error 1. Check the phase detection circuit to confirm that the input signal range is within the module range.

2. Adjust the control algorithm parameters to match the load characteristics.

Overheat protection triggers poor heat dissipation or load exceeds the limit 1. Clean the dust in the module heat sink and check the fan operation status.

2. Reduce the load or upgrade to a higher power module.

Key maintenance steps

Regular inspection:

Clean the heat sink every 6 months and check the oxidation of the connector.

Perform self-diagnosis test every year and back up program files.

Environmental requirements:

Install in a dry, dust-free environment, temperature -25℃ to 70℃, protection level IP20.

Avoid exposure to corrosive gases or liquids.

Safe operation:

Cut off the main power supply before maintenance and avoid live work.

Use original accessories and follow ABB’s official maintenance process.

Compatibility and alternatives

1. System compatibility

Recommended system: ABB ACS6000 medium voltage drive system, supporting multi-motor coordination on common DC bus.

Extended compatibility: Integrate with controllers such as AC 800M and PM891 to achieve unified monitoring.

https://www.weikunfadacai1.com/product/s-073n-high-voltage-inverter-phase-module-3bhb009884r0021-35shy3545l0014-s-073n/