Description

Many products are not yet on the shelves. Please contact us for more products.

If the product model is inconsistent with the display picture, the model shall prevail. Please contact us for specific product pictures, and we will arrange to take photos in the warehouse for confirmation.

We have 76 shared warehouses around the world, so sometimes it may take several hours to return to you accurately, please understand. Of course, we will respond to your concerns as soon as possible.

S-073N 3BHB009884R0021 Other names:

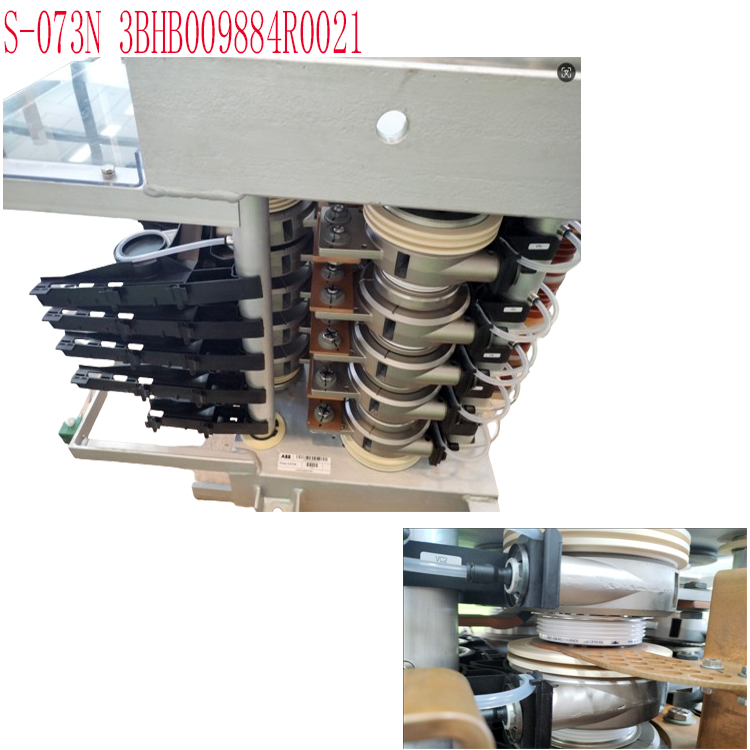

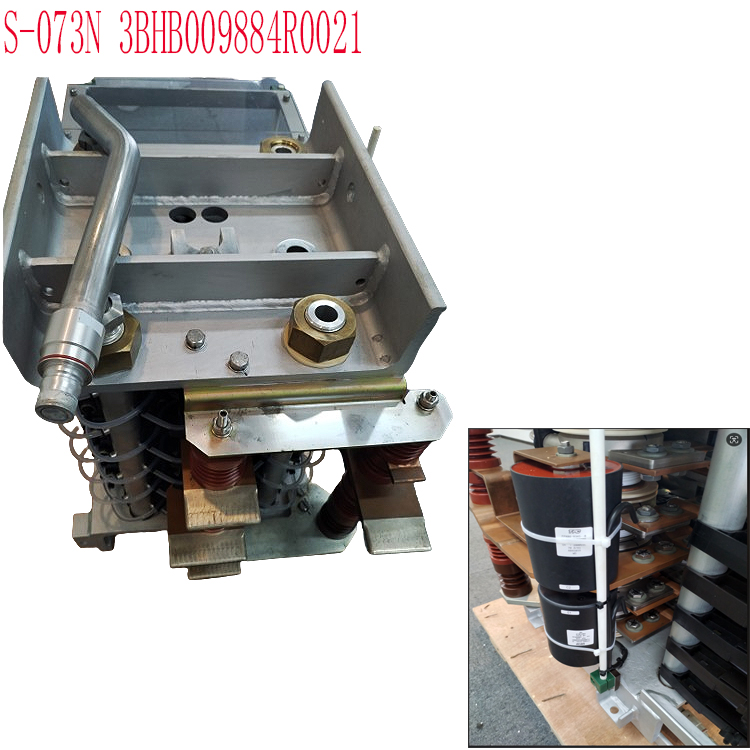

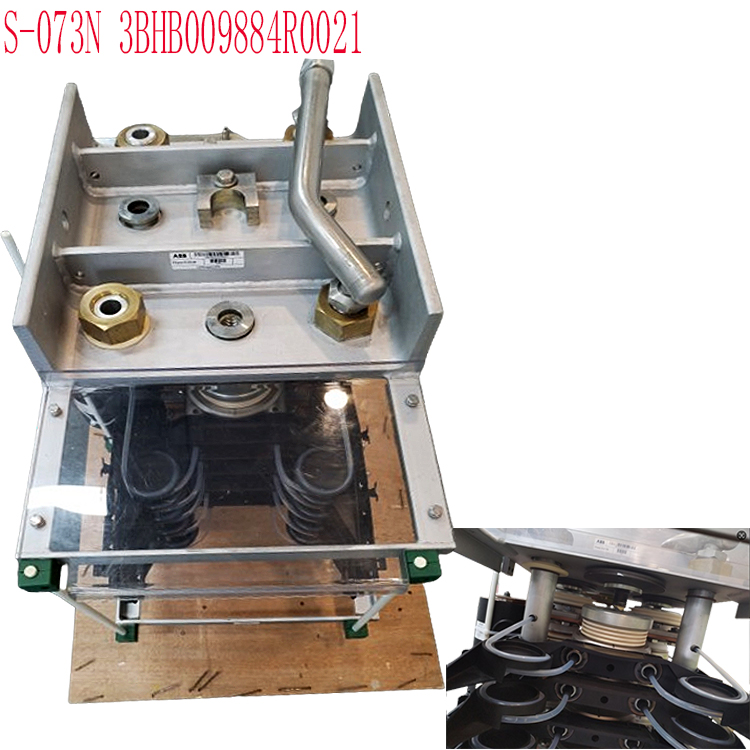

IGCT module S-073N 3BHB009884R0021

S-073N 3BHB009884R0021 control unit

Input and output module S-073N 3BHB009884R0021

ABB S-073N 3BHB009884R0021 is a high-voltage inverter phase module, which is composed of semiconductor switching devices (such as transistors, thyristors, etc.). Its function is to convert direct current (DC) into alternating current (AC) and provide it to the load. To meet the needs of various loads. In high-voltage applications, ABB high-voltage inverter phase modules can provide stable and efficient power conversion. This high-voltage inverter phase module plays a key role in power conversion and control. It belongs to ABB’s high-voltage inverter series. This type of product is mainly used in high-voltage power systems, especially in the design and testing of power electronic equipment.

Working principle

The working principle of the S-073N 3BHB009884R0021 inverter phase module is to convert direct current into alternating current by using the switching characteristics of semiconductor switching devices. When the semiconductor switching device is turned on, the current passes through the load and generates a sinusoidal alternating current; when the semiconductor switching device is turned off, the current is cut off and the voltage on the load drops to zero. By controlling the on and off time of the semiconductor switching device, the frequency and voltage amplitude of the output alternating current can be adjusted.

Main features and functions

High-voltage design: This module is designed to handle high-voltage circuits and can withstand voltages of up to several thousand volts.

Precision control: It can accurately control the voltage and current in the AC circuit, suitable for various high-precision power electronic applications.

Versatility: It usually contains multiple functions, such as switching, current limiting, overvoltage protection, etc., to improve the reliability of the overall system.

High temperature operation: The design takes into account the working performance in high temperature environment and is suitable for use in harsh conditions.

Programmability: Some versions may support software configuration, allowing users to adjust parameters according to needs.

High efficiency: ABB’s high-voltage inverter phase module S-073N 3BHB009884R0021 adopts advanced semiconductor switching devices and circuit design, which can achieve efficient power conversion and reduce energy loss.

High reliability: The module has undergone strict quality control and reliability testing, has excellent stability and durability, and can operate stably for a long time under harsh working conditions.

High power density: ABB’s high-voltage inverter phase module S-073N 3BHB009884R0021 adopts a compact structure design, high power density, small footprint, and easy installation and maintenance.

Flexible configuration: ABB provides inverter phase modules of various models and specifications, which can be flexibly configured according to actual needs to meet different power conversion needs.

Application fields

ABB high-voltage inverter phase module S-073N 3BHB009884R0021 is widely used in various occasions where high-voltage DC power needs to be converted into AC power, such as power, communication, transportation, energy and other fields. In the power system, it can be used to achieve long-distance transmission and distribution of electric energy; in the communication system, it can provide stable AC power for communication equipment; in the transportation field, it can be used for electric vehicle charging stations and rail transit power supply systems; in the energy field, it can be used for renewable energy (such as solar energy, wind energy) power generation systems.

Power industry: used in power system reactive power compensation, active filtering and harmonic suppression.

Transportation: Provide stable high-voltage power for electric vehicle charging stations, rail transit and ships.

Industrial manufacturing: Provide the required AC power in automated production lines, robots and CNC machine tools.

New energy: In solar and wind power generation systems, convert DC power into AC power and feed it into the power grid.

ABB high-voltage inverter phase module S-073N 3BHB009884R0021 is a high-performance, high-reliability and easy-to-maintain power electronic component, which is widely used in various occasions requiring high-voltage power conversion. In the selection and use process, users need to fully consider the actual application needs and conditions, and comply with relevant operating specifications and maintenance requirements to ensure its stable operation and extended service life.

All products on this website are special products, and the market price has been fluctuating.

Specific reference is made to the customer service quotation, because the product is a new product, the price is not real,

Please confirm the model and product, price and other details with the customer service before placing an order. The website has been used.

New ones are on sale, please contact customer service for communication.

Related product recommendations:

ABB 5SHY3545L0014 3BHB020720R0002

ABB 5SHY4045L0003

5SHY4045L0003 3BHE019719R0101

5SHY4045L0003 3BHB021400 3BHE019719R0101

5SHY3545L0005 336A4954ARP2

KUC321AE HIEE300698R1

KUC711AE 3BHB004661R0001

KUC720AE 3BHB000652R0001

GFD233A101 3BHE022294R0101

GFD563A102 3BHE046836R0102

GF D563 3BHE046836R010

3BHE017628R0002 PPD115A02

PPD517A3011 3BHE041576R3011

PCD232A 3BHE022293R0101

PCD237A101 3BHE028915R0101

PCD230A 3BHE022291R0101

PCD231B 3HHE025541R0101

PCD235C101 3BHE057901R0101

More……

admin –

ABB S-073N 3BHB009884R0021 is a high-voltage inverter phase module, which is composed of semiconductor switching devices (such as transistors, thyristors, etc.). Its function is to convert direct current (DC) into alternating current (AC) and provide it to the load. To meet the needs of various loads. In high-voltage applications, ABB high-voltage inverter phase modules can provide stable and efficient power conversion. This high-voltage inverter phase module plays a key role in power conversion and control. It belongs to ABB’s high-voltage inverter series. This type of product is mainly used in high-voltage power systems, especially in the design and testing of power electronic equipment.

admin –

The working principle of the S-073N 3BHB009884R0021 inverter phase module is to convert direct current into alternating current by using the switching characteristics of semiconductor switching devices. When the semiconductor switching device is turned on, the current passes through the load and generates a sinusoidal alternating current; when the semiconductor switching device is turned off, the current is cut off and the voltage on the load drops to zero. By controlling the on and off time of the semiconductor switching device, the frequency and voltage amplitude of the output alternating current can be adjusted.

admin –

Application fields

ABB high-voltage inverter phase module S-073N 3BHB009884R0021 is widely used in various occasions where high-voltage DC power needs to be converted into AC power, such as power, communication, transportation, energy and other fields. In the power system, it can be used to achieve long-distance transmission and distribution of electric energy; in the communication system, it can provide stable AC power for communication equipment; in the transportation field, it can be used for electric vehicle charging stations and rail transit power supply systems; in the energy field, it can be used for renewable energy (such as solar energy, wind energy) power generation systems.

admin –

Main features and functions

High-voltage design: This module is designed to handle high-voltage circuits and can withstand voltages of up to several thousand volts.

Precision control: It can accurately control the voltage and current in the AC circuit, suitable for various high-precision power electronic applications.

Versatility: It usually contains multiple functions, such as switching, current limiting, overvoltage protection, etc., to improve the reliability of the overall system.

High temperature operation: The design takes into account the working performance in high temperature environment and is suitable for use in harsh conditions.

Programmability: Some versions may support software configuration, allowing users to adjust parameters according to needs.

vorbelutr ioperbir –

You made certain good points there. I did a search on the issue and found nearly all people will go along with with your blog.

admin –

The phase controller module adopts a unique fault-tolerant design to improve the reliability and stability of the system and supports redundant configuration to ensure that when the main controller fails, the backup controller can quickly take over the control task and monitor the operating status of the equipment in real time, diagnose potential faults, and provide fault alarm information for timely maintenance and replacement.

https://www.axcontroler.com/ABB/s-073n—abb—phase-controller-module—3bhb009884r0021—s-073n

https://www.axcontroler.com/ABB/s-073n—abb—phase-controller-module—3bhb009884r0021—35shy3545l0014

https://www.axcontroler.com/ABB/abb-3bhb009884r0021-process-control-module

https://www.axcontroler.com/ABB/abb-s-073n-3bhb009884r0021-process-control-module

https://www.axcontroler.com/ABB/3bhb009884r0021—abb—phase-controller-module—3bhb009884r0021

admin –

Technical features The ABB 3BHB009884R0021 phase controller module has the following technical features: High precision: using advanced control algorithms and technologies to ensure the accuracy and stability of phase control. Reliability: with multiple protection functions and fault diagnosis capabilities, it can operate stably in harsh environments. Scalability: supporting multiple communication protocols and interfaces, convenient for networking communication and expansion with other devices and systems. Ease of use: providing a friendly user interface and programming environment, convenient for users to configure, monitor and maintain. Fault tolerance and reliability: adopting a unique fault-tolerant design to improve the reliability and stability of the system, supporting redundant configuration, ensuring that when the main controller fails, the standby controller can quickly take over the control task. Data acquisition and monitoring: real-time acquisition of current, voltage and other power parameters, and processing and storage. Provide data monitoring and alarm functions to detect and handle abnormal situations in a timely manner.

https://www.axcontroler.com/ABB/s-073n—abb—phase-controller-module—3bhb009884r0021—s-073n

https://www.axcontroler.com/ABB/s-073n—abb—phase-controller-module—3bhb009884r0021—35shy3545l0014

https://www.axcontroler.com/ABB/abb-3bhb009884r0021-process-control-module

https://www.axcontroler.com/ABB/abb-s-073n-3bhb009884r0021-process-control-module

https://www.axcontroler.com/ABB/3bhb009884r0021—abb—phase-controller-module—3bhb009884r0021

admin –

Output power: 750W, current range 0-3A.

Control mode: supports position, speed, torque control, and has DCS-Link communication function (point-to-point high-speed data exchange).

Power semiconductor: uses IGCT (integrated gate commutated thyristor), supports high voltage (up to 3.3kV), large current, low conduction loss, and fast switching capability.

Circuit design: three-level topology, improve energy efficiency, simplify circuit complexity.

Key functions

Phase precision control:

Real-time monitoring of input voltage/current phase, adjusting output phase through advanced algorithms to ensure the best power supply phase for the motor.

In multi-motor synchronization scenarios (such as rolling mill drive), ensure the phase consistency of each motor to avoid vibration, noise and efficiency loss.

Dynamic response:

Based on direct torque control (DTC) technology, quickly adapt to load mutations (such as crusher material changes) and maintain stable torque output.

In wind power, chemical pumps and other scenarios, adapt to load characteristic changes and optimize operating efficiency.

Protection and reliability:

Built-in overvoltage, overcurrent, and short-circuit protection, support fast demagnetization (protect the generator in case of fault).

Modular design, support hot plugging, shorten maintenance downtime.

Industrial-grade design, adapt to harsh environments (high temperature, high humidity, vibration).

admin –

ABB S-073N (model: 3BHB009884R0021) is the core phase control module of the ACS6000 medium voltage inverter system. It is designed for high-voltage motor drive and is suitable for precise speed regulation and energy optimization in industries such as power, metallurgy, and chemical industry. It adopts three-level circuit topology and IGCT (integrated gate-controlled thyristor) technology, with high reliability, high efficiency and low harmonic characteristics.

Technical specifications and functions

1. Core parameters

Electrical parameters:

Input voltage: DC 200-750V (suitable for wide range power supply)

Output power: 750W (support high-voltage motor drive)

Current range: 0-3A (precise control of motor torque)

Control mode: support position, speed, torque triple control

Circuit design:

Three-level topology: use IGCT devices to reduce switching losses and improve efficiency

Buffer absorption circuit: integrated inductor (L1/L2), resistor (R) and diode (D3/D4) to suppress voltage spikes

Communication capability:

DCS-Link: high-speed point-to-point communication, realize direct data exchange between drivers

Pulse input: up to 5MHz, support high-precision position feedback

2. Key functions

Phase synchronization control: ensure phase consistency when multiple motors are running in coordination, avoiding vibration and efficiency loss

Energy optimization: realize braking energy recovery through the common DC bus to reduce grid energy consumption

Environmental adaptability: industrial-grade design, resistant to high temperature, high humidity and vibration environment

Application scenarios

1. Power industry

Power plant: drive boiler fan, induced draft fan and water pump to achieve soft start and energy-saving speed regulation

Substation: used for voltage regulation and reactive power compensation to ensure grid stability

2. Metallurgy and mining

Steel plant: rolling mill multi-motor coordinated control to ensure rolling accuracy and surface quality

Mining equipment: crusher, hoist drive, adapt to load mutation and harsh working conditions

3. Chemical and pharmaceutical

Large mixer: precise speed control of material mixing in the reactor

Centrifuge: optimize the separation process and improve product purity

4. Renewable Energy

Wind Power Generation: Power Conversion and Grid-Connected Control, Improve Wind Energy Utilization

Troubleshooting and Maintenance Recommendations

1. Common Problems and Solutions

Possible Causes of Fault Phenomena Solution Steps

Module No Response Power Abnormality or Communication Interruption1. Check DC 200-750V Input Stability.

2. Verify DCS-Link Communication Line Connection.

3. Update the firmware to the latest version.

Phase Control Deviation Pulse Input/Encoder Fault1. Calibrate Pulse Input Frequency (≤5MHz).

2. Check the encoder feedback line to ensure no interference.

Overheating Protection Triggers Poor Heat Dissipation or Overload1. Clean the Dust on the Heat Sink and Check the IGCT Junction Temperature (≤125℃).

2. Reduce the load or upgrade to a higher power module.

admin –

ABB S-073N (model: 3BHB009884R0021) is the core phase control module of the ACS6000 medium voltage inverter system. It is designed for high-voltage motor drive and is suitable for precise speed regulation and energy optimization in industries such as power, metallurgy, and chemical industry. It adopts three-level circuit topology and IGCT (integrated gate-controlled thyristor) technology, with high reliability, high efficiency and low harmonic characteristics.

Technical specifications and functions

1. Core parameters

Electrical parameters:

Input voltage: DC 200-750V (suitable for wide range power supply)

Output power: 750W (support high-voltage motor drive)

Current range: 0-3A (precise control of motor torque)

Control mode: support position, speed, torque triple control

Circuit design:

Three-level topology: use IGCT devices to reduce switching losses and improve efficiency

Buffer absorption circuit: integrated inductor (L1/L2), resistor (R) and diode (D3/D4) to suppress voltage spikes

Communication capability:

DCS-Link: high-speed point-to-point communication, realize direct data exchange between drivers

Pulse input: up to 5MHz, support high-precision position feedback

2. Key functions

Phase synchronization control: ensure phase consistency when multiple motors are running in coordination, avoiding vibration and efficiency loss

Energy optimization: realize braking energy recovery through the common DC bus to reduce grid energy consumption

Environmental adaptability: industrial-grade design, resistant to high temperature, high humidity and vibration environment

Application scenarios

1. Power industry

Power plant: drive boiler fan, induced draft fan and water pump to achieve soft start and energy-saving speed regulation

Substation: used for voltage regulation and reactive power compensation to ensure grid stability

2. Metallurgy and mining

Steel plant: rolling mill multi-motor coordinated control to ensure rolling accuracy and surface quality

Mining equipment: crusher, hoist drive, adapt to load mutation and harsh working conditions

3. Chemical and pharmaceutical

Large mixer: precise speed control of material mixing in the reactor

Centrifuge: optimize the separation process and improve product purity

4. Renewable Energy

Wind Power Generation: Power Conversion and Grid-Connected Control, Improve Wind Energy Utilization

Troubleshooting and Maintenance Recommendations

1. Common Problems and Solutions

Possible Causes of Fault Phenomena Solution Steps

Module No Response Power Abnormality or Communication Interruption1. Check DC 200-750V Input Stability.

2. Verify DCS-Link Communication Line Connection.

3. Update the firmware to the latest version.

Phase Control Deviation Pulse Input/Encoder Fault1. Calibrate Pulse Input Frequency (≤5MHz).

2. Check the encoder feedback line to ensure no interference.

Overheating Protection Triggers Poor Heat Dissipation or Overload1. Clean the Dust on the Heat Sink and Check the IGCT Junction Temperature (≤125℃).

2. Reduce the load or upgrade to a higher power module.

Key Maintenance Steps

Regular Inspection:

Clean the heat dissipation channel every 6 months and check the oxidation of the connector.

Perform a self-diagnosis test once a year and back up the configuration file.

Module replacement:

Use the “Replace unit” function of the AC 800M controller to retain the original configuration.

Confirm that the new module model (such as S-076N) is compatible with the system.

Compatibility and alternatives

1. System compatibility

Controller: Seamlessly integrated with the AC 800M series (such as PM891), supporting Profibus and Modbus protocols.

I/O module: Compatible with the S800 series to achieve multi-motor coordinated control.

2. Alternative models

Upgrade options: If S-073N is discontinued, it is recommended to choose a new generation of phase modules (such as S-076N 3BHB009884R0021), and it is necessary to confirm:

The mechanical dimensions are compatible with the original cabinet.

The electrical interface (such as DCS-Link) is consistent.

https://www.weikunfadacai1.com/product/s-073n-abb-high-voltage-inverter-phase-module-3bhb009884r0021-s-073n/

admin –

Migration and support of ABB Advant Controller 250, a compact ABB Satt DCS process controller for medium to large size applications.Advant Controller 250 is a comprehensive process control vehicle for medium to large size applications. The same I/O units can be used either centrally or remote, and it is possible to combine the two in a single Advant Controller 250 configuration.

There are several controllers varying in the capability of handling I/O, execution speed and memory size. This means that you get the opportunity to choose the cheapest and the most suitable solution. The system is scalable in terms of adding communication modules, more powerful processor modules and more I/O modules as the demand increases.

The Advant Controller 250 has the possibility to communicate on several standard protocols e.g. MMS on TCP/IP Ethernet, COMLI, SattBus and PROFIBUS-DP for I/O. It is also possible to write your own serial ASCII protocol with standard function block.

The compact dimensions save on space and the integrated terminal strips reduce cabling requirements, save installation time and increase installation reliability.

Advant Controller 250 life cycle status

Advant Controller 250 is in the Limited life cycle phase.

Customers are encouraged to migrate Advant Controller 250 to AC 800M.

Advant Controller 250 benefits:

safety functions in I/O

same I/O units remote and central

modularity facilitates configuration and expansion

choice of CPUs gives opportunity to optimise

admin –

SattCon 200 for Satt DCSABB SattCon 200, a compact ABB Satt process controller for medium to large size applications with integrated terminal strips.SattCon 200 is a comprehensive process control tool for medium to large size applications. The same I/O units can be used either centrally or remote, and it is possible to combine the two in a single SattCon 200 configuration.

With many control systems, you have to accommodate various functions, such as alarm handling, outside the system. Not with the SattCon 200. The list of standard functions includes 16 separate PLC program modules, registers for data storage, recipe handling, excellent loop control capability, timers and counters, text handling facility, advanced alarm handling, autotuner, ready-to-use PID controllers and integrated communication.

The compact dimensions save on space while the integral terminal strips reduce cabling requirements and save installation time.

SattCon 200 life cycle status

Series 200 is in the Active life cycle phase.

ABB has conversion tools available to migrate SattCon 200 to AC 800M, with proven use in several plants.

AC 800M

Modular DCS process controller in several CPU modules from low cost, medium power to high-power and full redundancy